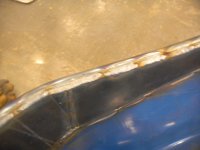

I've been mig welding sheet metal in the auto body repair business for decades.

It's generally thinner than 14ga.

Many in my business like to use use .023 wire.

I actually prefer .030 wire. And, I can weld thin metal quite well with it. So, I can tell you it can be done.

.030 is generally called for in the factory service manuals, to make plug welds, when doing structural repairs.

I prefer not to use flux core, it is great if you have to weld outside in the wind. But, it splatters too much for me.

I use a Co2/argon mix. And, I like the welder set up a little hotter than most people.

It takes time to develop the skills to do it well. The more you do it, the better you should be.

It's generally thinner than 14ga.

Many in my business like to use use .023 wire.

I actually prefer .030 wire. And, I can weld thin metal quite well with it. So, I can tell you it can be done.

.030 is generally called for in the factory service manuals, to make plug welds, when doing structural repairs.

I prefer not to use flux core, it is great if you have to weld outside in the wind. But, it splatters too much for me.

I use a Co2/argon mix. And, I like the welder set up a little hotter than most people.

It takes time to develop the skills to do it well. The more you do it, the better you should be.