Some of this has been addressed already but I'm going to hit it again as part of one big answer

So yes it's a hard line that goes from the loader valve back to the remote/auxiliary valve at the rear. As such I don't see how to put my valve between the 2. (As much as I like that idea. )

I suppose technically I could completely remove that hard line, go directly from the loader valve to my new valve, and then run another new line to the in port on the remote/auxiliary valve.

But that raises lots of challenges as there's not much space at both ends of that hard line. (At the loader valve it comes off at a 90 to go back. ) not to mention figuring out what that threading is where it connects to the valve. I'll see if I can dig up info on the loader valve later on today.

On our CK35 the hard line from the FEL valve terminates into the rear end housing of the tractor but the remotes bolt up the same to a proprietary mating surface on the side of the rear end housing - so they're getting their flow from internal to the tractor instead of directly from the hard line like yours, however the process for replacing the hard line with 2 rubber lines is the same (and actually pretty easy)

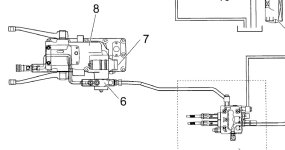

I "split" this line (replaced it) to install a solenoid valve to act as a 3rd function on the FEL for a grapple. In that configuration there is no PB port (just P, T, and 2 work ports). All flow exiting one side of the valve is dumped downstream through the T port to the next "thing" in series and when the solenoid valve is not in operation, full system pressure goes in P, through the block, and out T to the rear of the tractor.

In my case that's alright because all the ports are milled in the same aluminum block so all of them can withstand the same pressure, however generally speaking T returns flow at a reduced pressure whereas PB is still full system operating pressure and you should verify your valve can be configured to operate this way, otherwise you are correct in that you will need to also somehow plumb the T port back to a tank line (which the best I can figure due to kioti's proprietary mounting of these rear SCV's - would be all the way up front on the FEL valve) and the PB port back to your factory rear remote.

As to the fittings / threads on the hard line, I'm willing to bet the FEL valve side is the same as ours, in which case it's a banjo type head on the hard line with a thru bolt into the valve body and it's 18mm metric.

Get an 18mm Male to 1/2" JIC Male 90* fitting and screw into the valve and that gets you pointed rearward quick & in little space. After that the hydraulic shop can match whatever is on the other end on your factory rear spool. Get an adapter for that to 1/2 JIC Male then get all the hoses with 1/2" JIC female and you won't need to worry about any twists routing the hose or adding swivels to tighten everything up good.

I have attached the write-up I did on our 3rd function valve. While it's not exactly the same thing, it holds a lot of basic similarities to what you want to do, so it might be some good reading for you.

Best of luck whatever way you decide to go.