You keep saying that the nuts didn't loosen up, and I believe you. But I don't think that the nut loosening or not is the problem here. And it doesn't look like the diameter of the hole is either.

From a mechanical engineering point of view, conical nuts and tight-fitting wheel stud holes are nice, but those features are backups. In this type of joint, It should be the simple clamping pressure from the nut that does the work of keeping the wheel tight enough to the axle face so that it doesn't move.

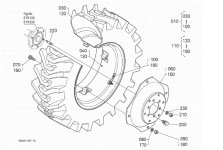

From what you say, it simply looks like the clamping pressure is insufficient to keep the wheel from moving. And that is such a simple calculation that I can't believe that Kubota got it wrong. Al, when I look at that picture you posted of the stud, lock washer, and nut stack back at the beginning of this thread it just looks wrong to me. I seriously doubt that is a stock setup. Have you checked against an exploded parts diagram? It would be downright weird and unique if any joint like that was originally designed with a lock washer carrying the compressive force between the nut and wheel face.

So to me it seems like the nut and washer stack were assembled wrong when the tractor was new. Maybe by the dealer, or the tire shop, or some other place. At the least there should be a large hard flat washer between the wheel face and the nut.

rScotty