widefat

Platinum Member

- Joined

- Oct 7, 2015

- Messages

- 559

- Location

- Central Va

- Tractor

- Kubota L3200 Husq GT52XLS Husqvarna LC121P Husq 455 Rancher Stihl FS90 Stihl MS170 99 Ram 1500

Thanks for all of the input - the diversity of experience and expertise on this forum always amazes me.

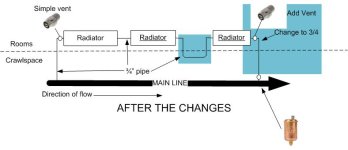

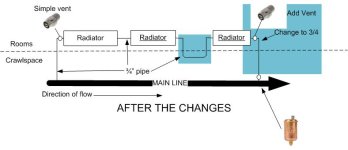

So here's the plan.

It worked before I messed with it. The only change I made was to create that trap with the four 90's

1 - Right now, that trap is actually lower than the main line. I am going to raise it above the main line and replace the two lower 90's with 22 degree sweeps.

This should both shorten the run and get rid of some of the friction.

2 - replace the section of 1/2 inch with 3/4. I dont know why it was installed with 1/2" - but that was 40 years ago.

3 - install a vent at high point/output of the last radiator in the circuit. I don't know why the vent (the #67) exists where it does, but I reckon I will leave it.

These are easy changes that I can knock out quickly.

If they dont work, I think I am in over my head.

So here's the plan.

It worked before I messed with it. The only change I made was to create that trap with the four 90's

1 - Right now, that trap is actually lower than the main line. I am going to raise it above the main line and replace the two lower 90's with 22 degree sweeps.

This should both shorten the run and get rid of some of the friction.

2 - replace the section of 1/2 inch with 3/4. I dont know why it was installed with 1/2" - but that was 40 years ago.

3 - install a vent at high point/output of the last radiator in the circuit. I don't know why the vent (the #67) exists where it does, but I reckon I will leave it.

These are easy changes that I can knock out quickly.

If they dont work, I think I am in over my head.