You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let's see some homemade 3 point ballast!

- Thread starter TractorNH

- Start date

- Views: 312905

More options

Who Replied?

/ Let's see some homemade 3 point ballast!

#141

Mandres

New member

Great pics, love it!

4get gto

Elite Member

- Joined

- Jan 20, 2010

- Messages

- 2,966

- Location

- N.E. Pa.

- Tractor

- Yanmar 147D with loader,Woods mow,n machine 6210 ,Sears st10,Roper rt 10

I want to know how you're holding the Deere in the bucket..?This is why ballast so is important....

NO ballast box...

View attachment 620289

About 500 pound ballast box...

View attachment 620290

Don't panic, these pic were staged under controlled conditions...

JD L120 weighs in at about 520 pounds according to JD...

Dale

WranglerX

Super Member

I want to know how you're holding the Deere in the bucket..?

Homemade bumper on front of Deere is wedged under lip of bucket....

Dale

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

Android phones too.Pictures taken with I-Phones don't always orient correctly, something APPLE has never really fixed.... Best solution before upload is to load pic into good graphics editor on real PC do any fixing and then save, then upload....

Some times the most modern technology is not your friend...

Dale

The reason is that its faster for the phone to always save the picture in the same direction and mark "this side up" in the file than it is for the phone to save the picture with the right side up.

Aaron Z

gabby

Gold Member

Dan Hunter

Platinum Member

Tony H

Platinum Member

- Joined

- Mar 18, 2013

- Messages

- 682

- Location

- Summit, NY lots of Lake Affect snow

- Tractor

- JCB MIDI CX / 1985 Cub Cadet 782

Just tossing this out there. When is it too much ballast? I know ballast is great for traction and Bucket balance However. When does the weight on the rear start to become a problem? Real Axle Bearings are strained. DL Meisen showed he can lift more weight with the Ballast that's all well and fine to help with the chores but how long will Front axles last if your ballast allows you to lift dirt all day rather then Hay bales?

Just looking for thoughts

Just looking for thoughts

k0ua

Epic Contributor

Just tossing this out there. When is it too much ballast? I know ballast is great for traction and Bucket balance However. When does the weight on the rear start to become a problem? Real Axle Bearings are strained. DL Meisen showed he can lift more weight with the Ballast that's all well and fine to help with the chores but how long will Front axles last if your ballast allows you to lift dirt all day rather then Hay bales?

Just looking for thoughts

I would think if you are having trouble keeping the front tires on the ground, then you might think about removing some of the rear ballast. Otherwise carry on.

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,395

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

I used to have 1000 lbs of ballast on my three point hitch. I removed it because if I was digging in the dirt a 1" rock was enough to push the bucket out of hard dirt. I removed 400 lbs and it's just about right. At 600 lbs it's nice for digging and it still keeps the back end on the ground for heavy loads. I shake my head at the amount of ballast some on TBN use. How can you get the bucket to dig into the ground?

k0ua

Epic Contributor

I used to have 1000 lbs of ballast on my three point hitch. I removed it because if I was digging in the dirt a 1" rock was enough to push the bucket out of hard dirt. I removed 400 lbs and it's just about right. At 600 lbs it's nice for digging and it still keeps the back end on the ground for heavy loads. I shake my head at the amount of ballast some on TBN use. How can you get the bucket to dig into the ground?

by correctly adjusting the angle of the bucket lip.

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,395

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

by correctly adjusting the angle of the bucket lip.

Ok so I agree that a 45 degree angle will get the bucket to dig in but a 1"stone will still roll the bucket up until there is a few lbs of dirt in the bucket. It was just way to frustrating. I'll stick with what I have and enjoy the control that I have. I'll still shake my head in wonder at people who have way too much weight as ballast.

PEJ5

Gold Member

It would be nice to have a way to calculate the correct/best weight, but there are so many variables - brand and size, FEL and 3Pt capacity, loaded rears, counterweight position, etc. I struggled to decide - I was going concrete so I only had one shot at it. I am happy with the result. My 2600LB FEL could not lift 1300 two feet out without the rear wheels lifting. With a 1300 counterweight on the 3Pt I feel more stable and should be able to safely 1500-2000+. Does this mean a counterweight of half your lift capacity makes sense for most? Hard to say.Ok so I agree that a 45 degree angle will get the bucket to dig in but a 1"stone will still roll the bucket up until there is a few lbs of dirt in the bucket. It was just way to frustrating. I'll stick with what I have and enjoy the control that I have. I'll still shake my head in wonder at people who have way too much weight as ballast.

WranglerX

Super Member

I have bombed around yard with the 500 lb ballast on tractor and bucket (FEL) empty and not had any steering problems or noticed front wheels off ground....

Also keep in mind FEL is not a "digging" tool its a scoop up and lift and dump tool...

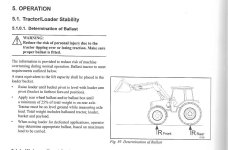

Also this is what my NF manual says about determining size of ballast...

Dale

Also keep in mind FEL is not a "digging" tool its a scoop up and lift and dump tool...

Also this is what my NF manual says about determining size of ballast...

Dale

Attachments

aeblank

Veteran Member

It would be nice to have a way to calculate the correct/best weight

The pivot point is the rear wheels.. the lever arm on a counterweight is so so so much shorter than it is to the loader pins.

If you wanted, measure from rear wheels to the loader pins. Measure from the rear wheels to the end of the 3pt arms. Divide one by the other (front/rear). Multiply that by your expected (max?) loader capacity.

I'd bet that you run out of 3pt capacity before reaching counterweight maxes. Mines like 1200# and is no issue on my L3940.

Imold

Platinum Member

- Joined

- Jul 23, 2019

- Messages

- 816

- Location

- West Central Mn.

- Tractor

- MF GC1705, Cub Cadet RZTL, Husqvarna Rider.

JK22

Gold Member

just finished my post on my build; Custom Rear Ballast and Tool Carrier Build

i was going to do a simple backyard build with a 55 gal drum or something, but then thought it'd look ghetto and i'd rather do something a lot cleaner and actually be multipurpose too.

check out the thread for more info.

View attachment 551476

View attachment 551477

-Haas

Wow. Very nice.

Here's the one I made for our 1526 tractor. Each iron disc is 200#. Bolted through a 26" drawbar with steel framework to hold it all in line. Needs some more paint and finish the brace on other side of the hook. At full down it clears level ground but needs to be raised for hills. Fits in really tight to the quick hitch which is great for clearance in tight spots. Couldn't fit all the weights on top of the drawbar so one had to go underneath. Tractor does much better with loads in the FEL bucket and forks.

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,395

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

Here's the one I made for our 1526 tractor. Each iron disc is 200#. Bolted through a 26" drawbar with steel framework to hold it all in line. Needs some more paint and finish the brace on other side of the hook. At full down it clears level ground but needs to be raised for hills. Fits in really tight to the quick hitch which is great for clearance in tight spots. Couldn't fit all the weights on top of the drawbar so one had to go underneath. Tractor does much better with loads in the FEL bucket and forks.

View attachment 632838

You are probably going to hate me but I would be tempted to just bolt the 26" bar to the top of all of those weights and not bother with the frame work. Then it's really easy to set on the ground to remove/reattach.