You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

L35 Engine valve adjustment

- Thread starter cheekme

- Start date

- Views: 9695

More options

Who Replied?

/ L35 Engine valve adjustment

#1

Roadworthy

Elite Member

I've not done an L35 but to adjust valves on my Mitsubishi I simply remove the valve cover. I put a socket on the nut on the front of the crankshaft to rotate the engine. My Mitsubishi is pretty easy to work on. The only reason for locating the timing mark is for timing the engine. If you're just adjusting valve lash you need only rotate the engine to the point where the given valve is fully closed and under no pressure from the rocker.

Chewwy

Platinum Member

- Joined

- May 5, 2015

- Messages

- 877

- Location

- Upstate SC, Near the Electric City

- Tractor

- Kubota L3240, MF 265, MF383

Per tractordata.com your L35 has the D1703 engine. Specific instructions for aligning the 1TC mark for valve adjustment on your D1703 engine are included on the attached page from my Kubota shop manual.

Per tractordata.com your L35 has the D1703 engine. Specific instructions for aligning the 1TC mark for valve adjustment on your D1703 engine are included on the attached page from my Kubota shop manual.

View attachment 627988

Thanks. Now if I can figure out where the flywheel inspection port is I'll be all set. I have a shop manual but it assumes way too much instead of putting in a simple graphic. It reads like the engine is sitting on a stand instead of in the tractor.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

With Kubota, usually on the right side under the floor board on the front of the bellhousing. Will have a Welch plug in it.

RalphVa

Super Member

- Joined

- Dec 19, 2003

- Messages

- 7,902

- Location

- Charlottesville, VA, USA

- Tractor

- JD 2025R, previously Gravely 5650 & JD 4010 & JD 1025R

I did it several times during the 25 years we owned the 1983 240D Benz. I just pushed on the fan belt and rotated the crankshaft with the plastic fan blades. Just be sure you're going in the right direction.

It's best if you can get a wrench on the nut on the end of the crankshaft, but this can be an access problem.

Ralph

It's best if you can get a wrench on the nut on the end of the crankshaft, but this can be an access problem.

Ralph

Chewwy

Platinum Member

- Joined

- May 5, 2015

- Messages

- 877

- Location

- Upstate SC, Near the Electric City

- Tractor

- Kubota L3240, MF 265, MF383

Thanks. Now if I can figure out where the flywheel inspection port is I'll be all set. I have a shop manual but it assumes way too much instead of putting in a simple graphic. It reads like the engine is sitting on a stand instead of in the tractor.

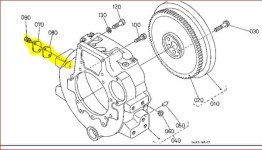

Highlighted in yellow on right side of the bell housing. You may have to remove right side loader frame to get access.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Though I don't often agree with Ralph, his way is the easiest and just watch the overhead and observe when both valves are completely extended. In my case I have 3 valves, one intake and 2 exhaust but it's still the same deal.

moship

Veteran Member

You can always use the EO/IC rule.

Watch the valve train when rotating the engine. Adjust Intake when the exhaust starts to open and adjust Exhaust when the intake is closing.

As long as the lift is on the base circle of the cam the valve can be checked.

Watch the valve train when rotating the engine. Adjust Intake when the exhaust starts to open and adjust Exhaust when the intake is closing.

As long as the lift is on the base circle of the cam the valve can be checked.

Smokeydog

Elite Member

Per the 4500 Ford backhoe shop manual, valve check and adjustment was done at operating temperature and while running. Had to be quick not to pinch your feeler gauge. That was the best running and cleanest oil of any diesel I’ve had.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Kubby's are all cold clearance.

Kubby's are all cold clearance.

The valves have never been adjusted and I'm at 2000 hrs currently. One reason is the difficulty of getting clearance around the top of the engine. Looks like at minimum the air cleaner and hoses would have to be removed. The fuel tank sits right over the number 3 cylinder and the loader support frame restricts access. Getting to the inspection port on the flywheel looks impossible, although that isn't a show stopper since observing valve opening turning the engine is easy. I've done multiple Google searches and never got a hit from anyone who has ever actually done it on the L35. At 800 hrs, the recommended interval for adjusting, I asked the Kubota dealer about it and he said, just run it so I have for another 1200 hrs. with no problems. I'm getting a rattle of sorts that could be the valves or could be some other harmonic vibration from engine combustion. Actually making the adjustment would take 10 min. if accessible was not an issue. Thanks for all the suggestions. BTW I've searched OrangeTractorTalks-Everything Kubota with no luck either. Next thought is to stop in at my local Kubota dealer and talk to an old timer mechanic who's seen everything.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Most units require removal if a certain amount of accessories / components to access and remove the valve cover, nothing new there. Just like a vehicle, to access the overhead requires removal of a certain amount of stuff.

The rattle you hear is most likely a rocker way out of adjustment. Setting the overhead will also restore lost power because sloppy valves don't open as far as they should and don't stay open as long as the should. I put off the valve adjustment on one of my M9's quite a while just because of the access issue and it was noticeable it was down on power and noisy (ticking) but it had to go in a few months ago (winter) for some work at the dealer so I had them set the overhead when it was there. They also put it on the dyno and it puts out (now) 93 PTO horsepower, quite a bit above the factory rated 85. It's quiet (as quiet as a direct injection diesel can be) ane the torque rise is back.

Valve adjustment plays a big part in how an engine runs and the noise it produces. Kubota engine are all solid lifter engines btw. No 'hydraulic lifters' to self adjust themselves.

The rattle you hear is most likely a rocker way out of adjustment. Setting the overhead will also restore lost power because sloppy valves don't open as far as they should and don't stay open as long as the should. I put off the valve adjustment on one of my M9's quite a while just because of the access issue and it was noticeable it was down on power and noisy (ticking) but it had to go in a few months ago (winter) for some work at the dealer so I had them set the overhead when it was there. They also put it on the dyno and it puts out (now) 93 PTO horsepower, quite a bit above the factory rated 85. It's quiet (as quiet as a direct injection diesel can be) ane the torque rise is back.

Valve adjustment plays a big part in how an engine runs and the noise it produces. Kubota engine are all solid lifter engines btw. No 'hydraulic lifters' to self adjust themselves.

captaintmb

New member

- Joined

- Oct 19, 2009

- Messages

- 1

I am replacing the head on my L35 and having the same problem with not being able to see the TDC mark to reset the valves (this is my first time EVER setting valves)…I noticed you got a lot of generic answers but none that addressed that we are not going to split the tractor or remove the loader to set the valves.Looking for a general procedure for accessing the engine top for valve adjustment and rotating engine to timing mark on flywheel. My L35 shop manual skips all this and just shows the adjustment which is the easy part.

What did you end up doing?