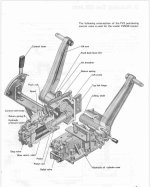

Hmm.... In message #15, the photo posted fine but doesn't help much. We need more views and larger. The drawing might be more helpful, but the resolution is illegible. EDIT (AN HOUR LATER: I CAN SEE THEM NOW. WHAT HAPPENED??) Also when you use contractions in the text it goes weird on my computer screen, making it hard to figure what you mean.

Is that just me or does that happen to anyone else too?

Maybe you could try adjusting the way that your computer interfaces with this TBN Forum. That might help both posting issues. Here is what I would do:

Go up to the heading "My Home" at the top of the Forum page. Then on the left hand column go down to

"My Settings" and from the list select "General Settings". In "General Settings" towards the bottom you will see "Message Editor Interface" and three choices of type of editor that you can use.

I like to use the first editor: Enhanced Interface - It is full "What You See Is What You Get" or WYSIWYG Editing.

Try that one and also try the other choices to see if there is one that will allow your text to post with contractions.

Also see if one of those will help with the resolution of the drawing you posted.

There are some other settings that might help too.

For instance no matter whether you are Mac or Windows based, there is usually a "develop" or "User" tab somewhere in the tool bar that gives you a choice of how a forum editor relates to which web browser you are using.

OK. Back to Tractors and hydraulics.

The picture in message #14 came through clear enough, but it doesn't make sense to me hydraulically.

I would rather see it plumbed the way I described.

And BTW, make sure your return line running from loader control valve back to the sump is larger diameter than your pressure line to the loader. The return line should also be as short as possible. The idea is to reduce back pressure on the return line.

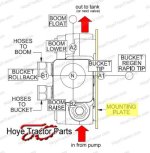

Also, I'm not clear if your loader valve has a power beyond port or not. Message #14 seems to say no PB port and #15 plus one of the drawings says it does. The other doesn't.

The power beyond port is NOT the same as the outlet (return) port. PB goes to another valve, return goes to the sump.

But you should always think about the following when using a new loader control valve:

Even when a loader control valve set has a power beyond or PB port, that port can be configured with plugs to fit two different types of hydraulic system. When you order a loader control valve it generally comes with both types of plugs that screw into the body of the loader control valve down inside the PB port. One plug is for an open center hydraulic system like you have. The other is for a closed center hydraulic system like some JDs have. You have to have the correct plug installed. If it's from Hoye, you probably do have the right one... if you have one at all....

Another piece of hydraulic scuttlebutt to think about.....When trouble-shooting or starting from scratch building a system you aren't familiar with..... you may find it easier to use a two lever FEL control valve with Open Center PB rather than any compact single joystick type. The old two lever controls are an older and simpler valve. So if you are buying by price, you can search around and get more control for your money with older two lever types. But that's probably NOT the problem here. Just saying......

luck, rScotty.

I’m working on my phone and for some reason anytime I add photos, any punctuation of any kind gets all jumbled up after I post. It only does that when photos are added. Sometimes I have the patience to go back and edit it so it’s proper, other times it’s overwhelming

My verbiage was incorrect in an earlier post when I stated I plumbed the outlet of the valve to the 3 point.

It wasn’t until I posted the Hoye’s control photos I realized I actually used the power beyond port and the outlet port was plugged out of the box.

I simply trusted how Hoye had the control setup with the temp plastic plugs for shipping was the proper ports to utilize.

Their control didn’t come with any instructions at all and the photos I posted were all I had to go off of when installing it.

I don’t suspect the loader valve to be the culprit as when I tested the output directly from the pump, it had filled a 1 gallon jug within about 30 seconds. Then when I tested the output of the control valve utilizing the hose that would be plumbed into the inout of the 3 point, it appeared to flow a similar rate.

As I understand, this valve is not intended to use both the loader and the 3 point simultaneously.

Also, this 3 point got stuck up like this once before on be before I ever installed a loader valve.

I suspect something is amiss within the 3 point itself causing pressure to flow into it, but not out. That’s where I get stuck since I have no real world experience with hydraulics to be able to reliably diagnose what the issue is.

It appears these are fairly simple mechanics, but without the knowledge of exactly what each piece does, it’s hard to break it down.

I’ll make a video tomorrow of exactly how I have it plumbed, and what I’m finding so as to better illustrate the condition.