plowhog

Elite Member

- Joined

- Dec 8, 2015

- Messages

- 4,048

- Location

- North. NV, North. CA

- Tractor

- Massey 1710 / 1758, Ventrac 4500Y / TD9

Update:

I cut 3 sections from the small part of the limb, about 8-10 ft long each. Diameter up to 10". Very small stuff compared to other pictures here. Pulled them one at a time, no problem. Not much sideways roll.

Now, I am hooked up to the "small end" of a 20' section. 10" diameter at the small end, 18" at the large end. My winch won't pull it. When I engage the winch, the line tightens, then the clutch slips. Limb doesn't move.

Not sure what is going on. The Farmi manual says there is a clutch adjustment possible, but this *is* a brand new winch?

Since it is a fallen limb, maybe when it came down, a side limb burrowed into the ground and is acting like an anchor?

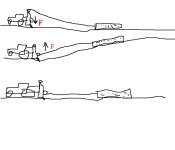

My cable is routed through the top pulley, then the bottom pulley, then through a snatch block at about 90 degree turn, then hooked onto the limb. Any ideas?

I cut 3 sections from the small part of the limb, about 8-10 ft long each. Diameter up to 10". Very small stuff compared to other pictures here. Pulled them one at a time, no problem. Not much sideways roll.

Now, I am hooked up to the "small end" of a 20' section. 10" diameter at the small end, 18" at the large end. My winch won't pull it. When I engage the winch, the line tightens, then the clutch slips. Limb doesn't move.

Not sure what is going on. The Farmi manual says there is a clutch adjustment possible, but this *is* a brand new winch?

Since it is a fallen limb, maybe when it came down, a side limb burrowed into the ground and is acting like an anchor?

My cable is routed through the top pulley, then the bottom pulley, then through a snatch block at about 90 degree turn, then hooked onto the limb. Any ideas?