KubotaCrossing

Member

.

.

I've got a ton of fencing to do this spring that will involve setting several hundred wooden fence posts.

I have a compact Kubota tractor ...

that I have rear remote "hydraulic-enabled" by tapping into the PowerBeyond port on the FrontEndLoader spool valve:

The specs say that the tractor hydraulic pump will produce three gallons per minute. Yeah that pretty low but it should be more than adequate for what I what to do, which is, lift a 300-400 pound weight then drop it letting it freefall. Yeah i know the setup looks fragile but I'm just doing proof of concept right now.

I was driving around in the Root the other day and saw a lonely contraption along the fence line in somebody's yard. Here in the Root, we don't use ForSale signs. If it's on the front lawn, that means it's for sale. I went up to the house and knocked on the door. The rest is history.

Anyway, I picked up a gem. It was probably in a previous life a 3pt-mounted, PTO-driven DanUser post pounder now mounted on a trailer. It was powered by a small gas engine that thru a rube goldsberg (sp?) set of chains and sprockets drove the DanUser friction wheel. The engine was shot. Instead of fixing the engine I removed it and all the friction-wheel/brake stuff. I installed a hydraulic cylinder, spool valve and hoses.

Here's the whole rig:

Shots of the fabricated hydraulic post pounder. Hey! Don't make fun of my welds. I did it with my eyes closed, well kind of, I have cataracts really bad.

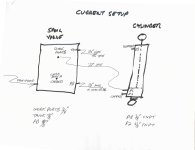

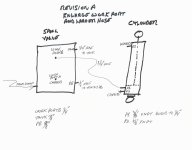

The setup of the hydraulic spool valve:

o Port bottom left: From pump (actually the PowerBeyond port on the FEL spool valve)

o Port top right: Return to tank. (actually the one gallon jug for now)

o Port bottom right: Return to tractor. (The other end of the PowerBeyond from the FEL spool valve that goes on to power the 3pt)

o Port top center: B port that goes to the base of the hydraulic cylinder.

o Port bottom center: A port capped. This would ordinarily go to the rod end of the hydraulic cylinder.

So what I've done here is taken a 4-way single bank spool valve and double-action hydraulic cylinder and converted to a 3-way single bank spool valve and single-action hydraulic cylinder. I have a hydraulic line only to the base of the cylinder and nothing but an air vent in the top port of the cylinder. ie I'm depending on the weight of the ram to retract (drop).

For anyone interested, here are the specs on the spool valve:

This monoblock valve is a hydraulic directional control valve. These valves are used to start and stop fluid flow into hydraulic cylinders or hydraulic motors.

Common Uses:

Operate hydraulic cylinders (Double-Acting or Single-Acting)

Operate hydraulic motors ("D" Spool Required)

Install rear remotes on a tractor

Benefits:

1 Spool valve with compact design allows for installations in tight areas

All spools are standard double acting with spring return to neutral position which are ideal for double acting cylinders

Used for open center systems (Pump to Tank Flow) - closed center option available

Anti-drop load checks on each spool

Precision ground and hard chrome-plated spools assure a long life

High-tensile strength cast iron monoblock construction

SAE O-Ring ports ensure solid seal and prevent blockages

Capable of closed center or Power Beyond (conversion plug required)

Vertical or horizontal handle mount

Adjustable Relief Valve Range: 1500 to 3625 PSI

Used as motor or single-acting spool possible (#8 SAE port plug required)

Features:

Max Operating Pressure: P = 3625 PSI, T = 725 PSI, A & B = 4350 PSI

Flow Rating: 11 GPM (40 l/min)

A & B Work Ports: #8 SAE O-Ring (3/4?16) Thread

Inlet Port: #10 SAE O-Ring (7/8?14) Thread

Outlet Port: #10 SAE O-Ring (7/8?14) Thread

2 5/16 Mounting Holes

Here are the specs on the hydraulic cylinder.

So, I put this all together and fired it up.

It works!

Well mostly. The cylinder extends fully. It's not really fast but it is acceptable.

The problem comes in when I retract the cylinder. The cylinder comes down at the same rate that it goes up. It comes down leaving a love-tap ... of course unacceptable for a post pounder.

I'm reaching out to the hydraulics brain trust here. Any suggestions on how to make this freefall?

.

I've got a ton of fencing to do this spring that will involve setting several hundred wooden fence posts.

I have a compact Kubota tractor ...

that I have rear remote "hydraulic-enabled" by tapping into the PowerBeyond port on the FrontEndLoader spool valve:

The specs say that the tractor hydraulic pump will produce three gallons per minute. Yeah that pretty low but it should be more than adequate for what I what to do, which is, lift a 300-400 pound weight then drop it letting it freefall. Yeah i know the setup looks fragile but I'm just doing proof of concept right now.

I was driving around in the Root the other day and saw a lonely contraption along the fence line in somebody's yard. Here in the Root, we don't use ForSale signs. If it's on the front lawn, that means it's for sale. I went up to the house and knocked on the door. The rest is history.

Anyway, I picked up a gem. It was probably in a previous life a 3pt-mounted, PTO-driven DanUser post pounder now mounted on a trailer. It was powered by a small gas engine that thru a rube goldsberg (sp?) set of chains and sprockets drove the DanUser friction wheel. The engine was shot. Instead of fixing the engine I removed it and all the friction-wheel/brake stuff. I installed a hydraulic cylinder, spool valve and hoses.

Here's the whole rig:

Shots of the fabricated hydraulic post pounder. Hey! Don't make fun of my welds. I did it with my eyes closed, well kind of, I have cataracts really bad.

The setup of the hydraulic spool valve:

o Port bottom left: From pump (actually the PowerBeyond port on the FEL spool valve)

o Port top right: Return to tank. (actually the one gallon jug for now)

o Port bottom right: Return to tractor. (The other end of the PowerBeyond from the FEL spool valve that goes on to power the 3pt)

o Port top center: B port that goes to the base of the hydraulic cylinder.

o Port bottom center: A port capped. This would ordinarily go to the rod end of the hydraulic cylinder.

So what I've done here is taken a 4-way single bank spool valve and double-action hydraulic cylinder and converted to a 3-way single bank spool valve and single-action hydraulic cylinder. I have a hydraulic line only to the base of the cylinder and nothing but an air vent in the top port of the cylinder. ie I'm depending on the weight of the ram to retract (drop).

For anyone interested, here are the specs on the spool valve:

This monoblock valve is a hydraulic directional control valve. These valves are used to start and stop fluid flow into hydraulic cylinders or hydraulic motors.

Common Uses:

Operate hydraulic cylinders (Double-Acting or Single-Acting)

Operate hydraulic motors ("D" Spool Required)

Install rear remotes on a tractor

Benefits:

1 Spool valve with compact design allows for installations in tight areas

All spools are standard double acting with spring return to neutral position which are ideal for double acting cylinders

Used for open center systems (Pump to Tank Flow) - closed center option available

Anti-drop load checks on each spool

Precision ground and hard chrome-plated spools assure a long life

High-tensile strength cast iron monoblock construction

SAE O-Ring ports ensure solid seal and prevent blockages

Capable of closed center or Power Beyond (conversion plug required)

Vertical or horizontal handle mount

Adjustable Relief Valve Range: 1500 to 3625 PSI

Used as motor or single-acting spool possible (#8 SAE port plug required)

Features:

Max Operating Pressure: P = 3625 PSI, T = 725 PSI, A & B = 4350 PSI

Flow Rating: 11 GPM (40 l/min)

A & B Work Ports: #8 SAE O-Ring (3/4?16) Thread

Inlet Port: #10 SAE O-Ring (7/8?14) Thread

Outlet Port: #10 SAE O-Ring (7/8?14) Thread

2 5/16 Mounting Holes

Here are the specs on the hydraulic cylinder.

So, I put this all together and fired it up.

It works!

Well mostly. The cylinder extends fully. It's not really fast but it is acceptable.

The problem comes in when I retract the cylinder. The cylinder comes down at the same rate that it goes up. It comes down leaving a love-tap ... of course unacceptable for a post pounder.

I'm reaching out to the hydraulics brain trust here. Any suggestions on how to make this freefall?