Commenting on my previous posts, I'll add that what I've said is based on what I've done, where I've worked. In every part of building, there is the ideal, best possible way of doing things, then there is what actually happens. The goal is to do everything possible to do it the best way possible, but knowing that things are going to happen that you have to deal with.

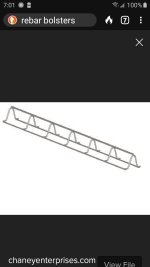

Rebar on chairs keeps it where it needs to be during a pour. Wire mesh has the potential to be better then rebar, but in my opinion and decades of experience, it always ends up at the bottom of the concrete when used on houses and large pads. This is 100% true in every case that I've ever come across, and in every picture that people have posted on here of their houses and barns being built.

As a contractor, I relocate toilets and drain lines all the the time. If they have rebar, it's usually in the middle of the concrete. I've only found it laying at the bottom a few times, and the amount of cracking was significant. On jobs like that, I refuse to install tile. Only a floating floor will last. In every house that I've found wire mesh, it's at the bottom and the cracking is also significant.

Welded wire on a house or barn slab is a waste of money and effort. Size of rebar and how far apart it has to be will vary by your location. After Katrina, they changed the Code for rebar, and then after houses where being built, they changed it again and some homes that had done it according to the first change had to tear it all out and do it again to meet Code. Spacing and size of rebar where the big changes that they where dealing with for those extreme conditions. I also heard that Florida keeps changing code for their rebar in slabs due to Hurricanes. Back in CA, where I'm from, it changes every year, and in every change, the size and amount of rebar required keeps increasing.

In my previous comments about a slump test, I'm not saying that your concrete has to remain standing after it comes out of the pail, I'm just trying to point out that it's where concrete needs to be for the best possible results. I doubt that anybody's house will ever pass the same tests used on sky scrapers, but it does give you an idea of where you are when the concrete is being poured. If the concrete comes out of your pail like soup, then there is way too much water. If it holds some sort of shape, even if it's more of a round hill, then you should be fine.

Most importantly, read up on what Code is for where you live. Weather and soil conditions will decide what you have to do.

The footings are what holds up your building. The slab is just for what goes on top of it, and secondary to the integrity of the structure.

In my entire life I've only seen a few houses with true foundation issues. The vast majority of issues that clients have claimed to be foundation problems are either structural issues in the attic, or lack of maintenance to their bricks that allowed water into the bricks and water to freeze. Since nobody is paying attention to their bricks when it freezes, and they usually notice the cracking when it's warm out, they tend to think it's a foundation problem. Sealing the windows and doors around the bricks, replacing the mortar will stop this from getting worse, or from ever happening. Attic issues are from using lumber that is too small for the span, storing stuff in the attic that is too heavy for the joists and somebody cutting away parts of the roof to get a pipe or duct through that area of the attic. AC units in attics cause a ton of issues too!!!

Soil compaction is probably the biggest reason for a true foundation failure, but it's extremely rare. It takes years for this to happen, and when it does, you can see where the concrete has cracked and sunk deeper into the ground.

Cracking the week or month after concrete is poured is always, 100%, from too much water in the mix.