You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

converting 3pt splitter to pull behind

- Thread starter Mallard1

- Start date

- Views: 7569

More options

Who Replied?

/ converting 3pt splitter to pull behind

#1

thanks, I'll have to look and see what size cylinder I currently have. I see most of the pumps put up 3,000 psi but the log splitter valves I was looking at are only rated for 2,000. am I missing something with this?

also I see most put up the same pressure just different GPM. does this just change the cycle time or are there other benefits of the higher GPM?

last on the tank size does the tank size need to be roughly equal to the GPM of the pump? such as a 15gpm pump needs a 15 gallon tank?

also I see most put up the same pressure just different GPM. does this just change the cycle time or are there other benefits of the higher GPM?

last on the tank size does the tank size need to be roughly equal to the GPM of the pump? such as a 15gpm pump needs a 15 gallon tank?

/pine

Super Star Member

- Joined

- Mar 4, 2009

- Messages

- 15,763

I just built a power unit for a splitter I had previously run off a ditch witch...

I already had a spare Predator 212cc engine so I bought a 10GPM pump, mounting bracket and lovejoy connector and a 10Gal tank, screen and filter...

out of all of it...even if I would have had to buy the 212 the tank was still the most expensive component...

I already had a spare Predator 212cc engine so I bought a 10GPM pump, mounting bracket and lovejoy connector and a 10Gal tank, screen and filter...

out of all of it...even if I would have had to buy the 212 the tank was still the most expensive component...

WranglerX

Super Member

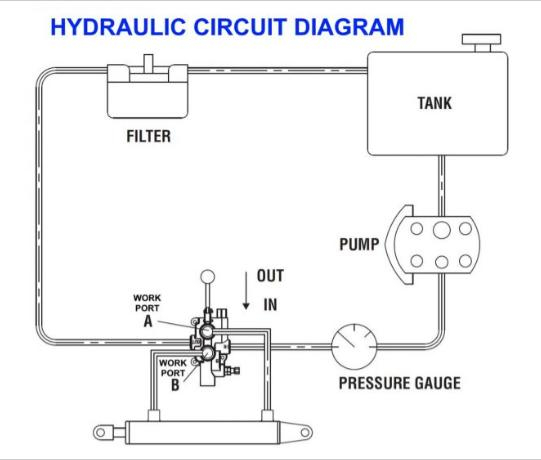

Many valves are "preset set" to 2000psi but many splitters are adjusted to go to 3000 psi.... Read spec on valves carefully there may be some statement about readjusting and maximum pressure valve is rated at.... My stand alone splitter has a 6.5 HP Predator motor (replaced 5 HP blown up B&S) that barely even changes pitch with the toughest oak logs.... Splitter is rated at 20 ton and If i have the math correct for a 4 inch diameter cylinder, the pressure relief on valve is set at 3000psi... The specs on my splitter states it has a 7 gallon tank... Also ideally pump should be two stage.... Not sure how familiar you may be with stand alone splitters, but diagram below shows all the essential parts and etc: (pressure gauge may be optional)

Last edited:

You can throttle back the relief valve..I believe most pumps or valves have them in them. Doing this makes pushing power less though.thanks, I'll have to look and see what size cylinder I currently have. I see most of the pumps put up 3,000 psi but the log splitter valves I was looking at are only rated for 2,000. am I missing something with this?

also I see most put up the same pressure just different GPM. does this just change the cycle time or are there other benefits of the higher GPM?

last on the tank size does the tank size need to be roughly equal to the GPM of the pump? such as a 15gpm pump needs a 15 gallon tank?

GPM is going to be your cycle time. Some box store splitters are horribly slow. The high/low style pumps like log splitters have helps this yet dosnt need a huge engine.

Yes 1gal tank size for every pump GPM. I used a 15gal keg for my hydraulic reservoir. Welded bongs on it along with a filler cap.

My engine is a 15hp lawnmower engine that I just cut the frame behind the engine and welded it on an I beam. It's a full time 4 way and will cut an oak round in half sideways.

crazyal

Super Member

I would price it out first and then price a similar splitter new. You may find that just selling what you have and getting a new one isn't going to cost you much more.

ericm979

Super Member

Unless you buy a high end splitter or have the major parts already it'll cost less to sell the 3pt and buy a standalone splitter than to build one out of your 3pt splitter.

If you do it, get the two speed pump.

If you do it, get the two speed pump.

inpo44

Bronze Member

- Joined

- Apr 6, 2012

- Messages

- 54

- Location

- Mid Missouri

- Tractor

- New Holland TC45D, TN60DA, Workmaster 37

I converted my Northern Tool 3pt to a stand alone splitter. It was good as a 3pt unit but I did not like having my tractor tied up running the splitter. The conversion allowed me to add a large out feed table and a log lifter. I used a Honda GX270 engine with MTE 16 gpm two stage pump, Prince hydraulic valves, and Harbor Freight air receivers repurposed a hydraulic tanks. Fun project.

Thank you for those pictures, I really like how that was done and that is exactly what I would like to end up with. any chance you have any other pictures? I see you put a pressure gauge on there, what pressure do you have the relief set at? also do you ever use a 4 way splitter on it or is there not enough force?I converted my Northern Tool 3pt to a stand alone splitter. It was good as a 3pt unit but I did not like having my tractor tied up running the splitter. The conversion allowed me to add a large out feed table and a log lifter. I used a Honda GX270 engine with MTE 16 gpm two stage pump, Prince hydraulic valves, and Harbor Freight air receivers repurposed a hydraulic tanks. Fun project.View attachment 711059View attachment 711060