BravoXray

Elite Member

- Joined

- Dec 17, 2019

- Messages

- 3,534

- Location

- Nothern Indiana

- Tractor

- Kubota BX2230, John Deere 430 Diesel

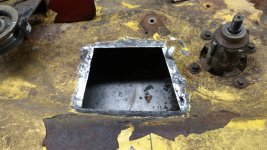

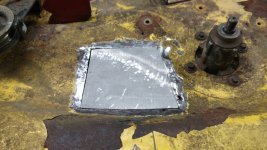

A friend asked if I could repair his mower deck, it had rusted and one of the idler pulley mounts tore loose. I said I'd give it a try. Didn't look too bad, someone had attempted to fix it a couple of years ago, and that repair had failed because of more of the area had rusted out. I cut out enough metal to get decent metal to weld a patch panel to, though it was still pretty thin in a few spots. Made a patch out of 11 ga. plate and spent some time getting it trimmed and the front side rolled up to make a better surface to weld to. I used my Miller 211 and got it tacked into place then welded it in place. I'm not a great welder, but the thin metal was a real challenge. I also had to do some cutting and grinding on the pulley mount to get it to lay parallel with the other pulleys, but I got it pretty close. Welded up some other cracks and loose deflectors, so it should be good to go for a while.

I used the BX to get it off the bench and set it outside.

I used the BX to get it off the bench and set it outside.

Attachments

-

275750429195902360 (Medium).jpg418.9 KB · Views: 361

275750429195902360 (Medium).jpg418.9 KB · Views: 361 -

IMG_20220415_161142207 (Medium).jpg719.2 KB · Views: 338

IMG_20220415_161142207 (Medium).jpg719.2 KB · Views: 338 -

IMG_20220415_172446227_HDR (Medium).jpg691.3 KB · Views: 350

IMG_20220415_172446227_HDR (Medium).jpg691.3 KB · Views: 350 -

IMG_20220415_173813174_HDR (Medium).jpg683.4 KB · Views: 336

IMG_20220415_173813174_HDR (Medium).jpg683.4 KB · Views: 336 -

IMG_20220416_142532067 (Medium).jpg785.1 KB · Views: 352

IMG_20220416_142532067 (Medium).jpg785.1 KB · Views: 352 -

IMG_20220416_151627909 (Medium).jpg905 KB · Views: 342

IMG_20220416_151627909 (Medium).jpg905 KB · Views: 342 -

IMG_20220417_115321461 (Medium).jpg915.1 KB · Views: 345

IMG_20220417_115321461 (Medium).jpg915.1 KB · Views: 345 -

IMG_20220417_121200412_HDR (Medium).jpg1,022.8 KB · Views: 375

IMG_20220417_121200412_HDR (Medium).jpg1,022.8 KB · Views: 375