I have a1951 Oliver OC3 crawler that has been equipped with a White 1010 loader probably since the 1970's. It's a light duty loader that was commonly found on Iseki tractors imported and re-badged by White. It had been operating well for 20+ years of my ownership, recently it has become reluctant to lower down. If I move the handle to the float position it lowers normally. When I try to power it down from any height the engine bogs and the inline pressure control valve emits a loud shrill as if fluid is rushing through it bypassing the control valves and returning to the reservoir. The engine will actually die trying to over come the load on the hydraulic pump, it's as if both sides of the lift cylinders are fully pressurized at the same time. My first inclination is to remove the lift/lower spool and clean it and it's bore in case there is something clogging any passageways.

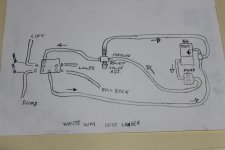

Attached is a somewhat crude diagram of the hydraulic system. Any suggestions would be welcome before I start taking things apart.

Attached is a somewhat crude diagram of the hydraulic system. Any suggestions would be welcome before I start taking things apart.