The nut is a RH thread. Heat until the nut until it is nearly orange, then let it cool, so as not to distort that 1/2" square opening. I used a 3/4" breaker bar, with 1/2" adapter, and still needed a 3' cheater on it, and I'm a good sized feller. It squawked, nearly the whole way off, every time you'd make a turn. After a half dozen turns, could turn it with a 3/4" ratchet. This was on an old 310B with a 148 gasser, but still had the same problem. This was approx. 12 years ago, and resorted to good ole' Google to find the answer. Here's a link to search results for loosening that nut.

https://www.google.com/search?q=D18...=AHkkrS4AAAAAYhmlP4OM9aXlbpqSRHGfbxCTMaqaiz7P Some suggest quenching the nut to cool it, but I just let it cool down by itself. Not down to room temp, but enough I could slap it with my fingers, and was still pretty warm. Some suggest using an impact, and to be honest, can't remember if I tried that or not, but do remember using the 3/4" drive, with 1/2" adapter, and cheater.

You may have a problem keeping the engine from rotating, I put the 310B in gear, and locked the brakes to hold the engine. If you have a torque converter, you may have to find a way to lock the flywheel, the engine compression just isn't enough.

I'm not sure if they put some sort of lock tite type material on the nuts from the factory, or what, But they can be a bear.

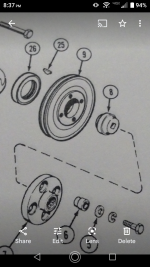

When it comes time to reinstall, torque the nut to 125-135 ft. lbs. I now have a '79 480C, and have the OEM repair manual in front of me, and that is the torque specs shown. Let us know how you get along with it.