2011laramie

New member

I recently picked up a used 3pt hitch tree spade. I got a 2014 kubota L4600 that I want to use with it.

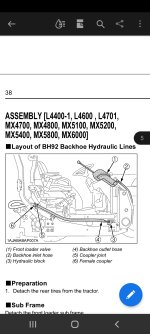

I don't have any rear remotes so I tried to bring power to the back by taking it off the power beyond port on the loader and run it to the back. Them the return back to the block under the floor board. Kinda like what they do for the backhoe setup.

Tonight was my 1st attempt at using it. The spade has an open center hydraulic valve setup. The tree spade works just fine, but the problem was the 3pt hitch won't lift the spade up. Not even when it's empty.

I had to swap hoses back to factory to get the spade lifted up.

Did I mess up with too small of hoses? The loader runs on 3/8 hoses so that's what I got made to run to the back. Or am I missing something.

I don't have any rear remotes so I tried to bring power to the back by taking it off the power beyond port on the loader and run it to the back. Them the return back to the block under the floor board. Kinda like what they do for the backhoe setup.

Tonight was my 1st attempt at using it. The spade has an open center hydraulic valve setup. The tree spade works just fine, but the problem was the 3pt hitch won't lift the spade up. Not even when it's empty.

I had to swap hoses back to factory to get the spade lifted up.

Did I mess up with too small of hoses? The loader runs on 3/8 hoses so that's what I got made to run to the back. Or am I missing something.