You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carport Weight

- Thread starter dieselscout80

- Start date

- Views: 9210

More options

Who Replied?

/ Carport Weight

#1

2manyrocks

Super Member

- Joined

- Jul 28, 2007

- Messages

- 9,516

I'd look on line for a similar carport to see what the shipping weight is.

I don't think weight will be your issue. The issue is that moving it will cause the frame to flex possibly tearing the roof around the fasteners unless you can figure out a way to stabilize it and go very slowly over a short distance.

I don't think weight will be your issue. The issue is that moving it will cause the frame to flex possibly tearing the roof around the fasteners unless you can figure out a way to stabilize it and go very slowly over a short distance.

Rustyiron

Super Member

I'd use 8 6" C clamps, 4-12' 2x4's and 7 strong buddies, and you making a guy on each leg.

jyoutz

Super Star Member

I think this is spot on. I have the same carport. It used to flex in the wind before I welded steel gussets to the corners to stop that. But the roof sheeting started to tear around some of the screws because of the movement. It’s a pain but I think the best option is to remove the roof panels, then move the carport. It will be a lot lighter and easier to move also and no chance of structural damage.I'd look on line for a similar carport to see what the shipping weight is.

I don't think weight will be your issue. The issue is that moving it will cause the frame to flex possibly tearing the roof around the fasteners unless you can figure out a way to stabilize it and go very slowly over a short distance.

ROUSTABOUT

Elite Member

- Joined

- Jan 30, 2008

- Messages

- 3,186

- Location

- Luther Willis Hill, AR

- Tractor

- Pettibone, Ford, Massey Ferguson, International, JD, David Bradley, home mades

When they build those sheds, it is all loaded on a 16' trailer behind a half ton truck. Bulk is your problem, not weight. So if you have something big enough to put it on, it will handle the weight. Haul it sideways and put the bottom runners on a trailer. Tie it down, keep it tied down at all times. Wind will easily roll it into a ball of scrap metal. Neighbor boy had one, oh yeah I'm gonna tie it down. Week later it was over in his neighbors pasture, crumpled up like a stomped can. Never touched the fence.

OP

dieselscout80

Veteran Member

We’re only moving it about 100 yards.

WranglerX

Super Member

Build a BIG skid and anchor it to skid and tow it by the skid...

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,006

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

Build a BIG skid and anchor it to skid and tow it by the skid...

Those carports aren’t that hard to disassemble. I might consider putting a piece of lumber at both ends for a spreader to keep the legs spaced apart and drag it but much beyond that you’d be faster to take it apart.

jyoutz

Super Star Member

Yes, and I am pretty sure that the roofing panels will get widened or torn at the screws fastener locations by moving. Then it leaks everywhere.Those carports aren’t that hard to disassemble. I might consider putting a piece of lumber at both ends for a spreader to keep the legs spaced apart and drag it but much beyond that you’d be faster to take it apart.

Have a 12x20 carport 8' walls moved a half dozen times around my property still standing no leaks very minor damage, I also moved a 20x24 12' high greenhouse off my polebarn still standing I did reinforce it with some steel extensively. Anyways I think if you can get two tractors lift it slightly on the base rails in the direction your dragging choke it under the base rail and a upright, and communicate well with the other operator you should be good. I can take pics of various reinforcement I did on green house before moving if you want. The 12' wide carport I didn't put extra reinforcement in it and used one tractor when moving. The green house I used one skid steer and a tractor and it was a straight pull. Good luck

OP

dieselscout80

Veteran Member

Thanks Jeff I’d like to see pi of how you did the moves.

nisaacs

Platinum Member

- Joined

- Mar 9, 2020

- Messages

- 783

- Location

- Snowflake, Arizona

- Tractor

- 970 John Deere 4x2, 970 John Deere 4x4, 4320 John Deere, 995 Case/IH

Those carports aren’t that hard to disassemble. I might consider putting a piece of lumber at both ends for a spreader to keep the legs spaced apart and drag it but much beyond that you’d be faster to take it apart.

I disagree. Wife and I built the frame then hired a contractor to do the roof. 6 hours for 2 guys, ladders, million screws, seals at all the joints, edge trim. To disassemble, you will need to mark all the sheets.

This is a 20'x24x8. After the roof, then we did both sides and one end. It took our old bones several days to do what we did. I would build another one at the new location before I would try to move it.

YanmarFever

Elite Member

- Joined

- Mar 10, 2002

- Messages

- 4,078

- Location

- Eating a melon..

- Tractor

- Mahindra 5010C- Branson 4520r- 5520C- Yanmar FX235-D - Bad Boy rogue mower

I moved ours with a forklift and some very wide lumber, they weigh hardly anything so watch the wind!

chim

Elite Member

Here's how someone on OTT did it:

www.orangetractortalks.com

www.orangetractortalks.com

Moving metal Carports

Hubby and I work VERY well together with hand signals. This video shows us moving a shed in complete coordination like a dance. Our hyper teenager video'd it so jumps a lot but you can see we move as one.

2manyrocks

Super Member

- Joined

- Jul 28, 2007

- Messages

- 9,516

Interesting....but personally I'd have used a heck of a lot more material to cross brace the carport before trying to move it.

OP

dieselscout80

Veteran Member

Kinda how I was thinking, but with one tract in the middle of the carport lifting from both opposite ends from how they did it.Here's how someone on OTT did it:

Moving metal Carports

Hubby and I work VERY well together with hand signals. This video shows us moving a shed in complete coordination like a dance. Our hyper teenager video'd it so jumps a lot but you can see we move as one.www.orangetractortalks.com

2manyrocks

Super Member

- Joined

- Jul 28, 2007

- Messages

- 9,516

Diagonal cross bracing in the form of an X would be more resistant to flexing that could cause tearing in the roof panels.

sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 6,314

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

We bought an 18 x 30 kit. had it rated for 55lb snow load and 150 MPH winds. It came in two pacs. The sheetmetal roofing was around 1200lb and the framing pac was just over 1700 lb IIRCWe’re only moving it about 100 yards.

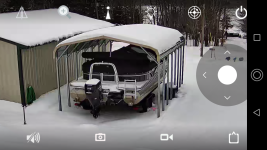

#7 picture of carport I've moved 1/2 doz times at least a few hundred feet in total. #1 and up are pics of green house I moved off the gable end of barn no pics of actually moving it out of learned mistakes I put phone and camera down when operating equipment lol anyways I know it's a lot heavier than any carport, had to cut lower uprights cause they were embedded in concrete, fortunately I had a lot of heavy gauge rusted repurposed angle iron lying around so I welded it around base and to cut uprights I also welded a piece of angle from the uprights below girder and welded srap angle diagonals in pic I removed center base piece I attached. To bottom of uprights left diagonals in place. One thing I can tell you is when moving it and it starts digging in ground stop immediately. Also when I moved green house I felt it may not make it but was ok if move failed and it came down cause other option was to tear I to down anyway I replaced green house on polebarn with another more usable structure. Any specific questions feel free to ask as my pics I took are snow covered and my explanation is probably lacking for some.

Attachments

Last edited:

OP

dieselscout80

Veteran Member

Thanks