binaryviking

New member

- Joined

- Feb 10, 2023

- Messages

- 13

- Tractor

- Massey Ferguson

Hello All

The left/right swing on my new backhoe attachment is way to fast, everything else works fine.

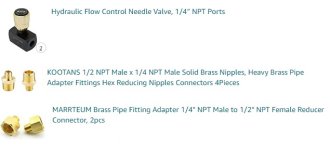

I was considering getting this adjustable flow control valve and putting it in right where the hydraulic hose hooks up to the controls for my swing , and then attaching the hydraulic host to it.

I'm thinking this will let me control the speed of my swing speed. I don't know all that much about hydraulics so I thought Id make a post to see if there might be anything I'm missing here.

Thanks for your help in advance!

The left/right swing on my new backhoe attachment is way to fast, everything else works fine.

I was considering getting this adjustable flow control valve and putting it in right where the hydraulic hose hooks up to the controls for my swing , and then attaching the hydraulic host to it.

I'm thinking this will let me control the speed of my swing speed. I don't know all that much about hydraulics so I thought Id make a post to see if there might be anything I'm missing here.

Thanks for your help in advance!