Gordon Gould

Super Member

- Joined

- Apr 1, 2007

- Messages

- 6,719

- Location

- NorthEastern, VT

- Tractor

- Kubota L3010DT, Kubota M5640SUD, Dresser TD7G Dozer

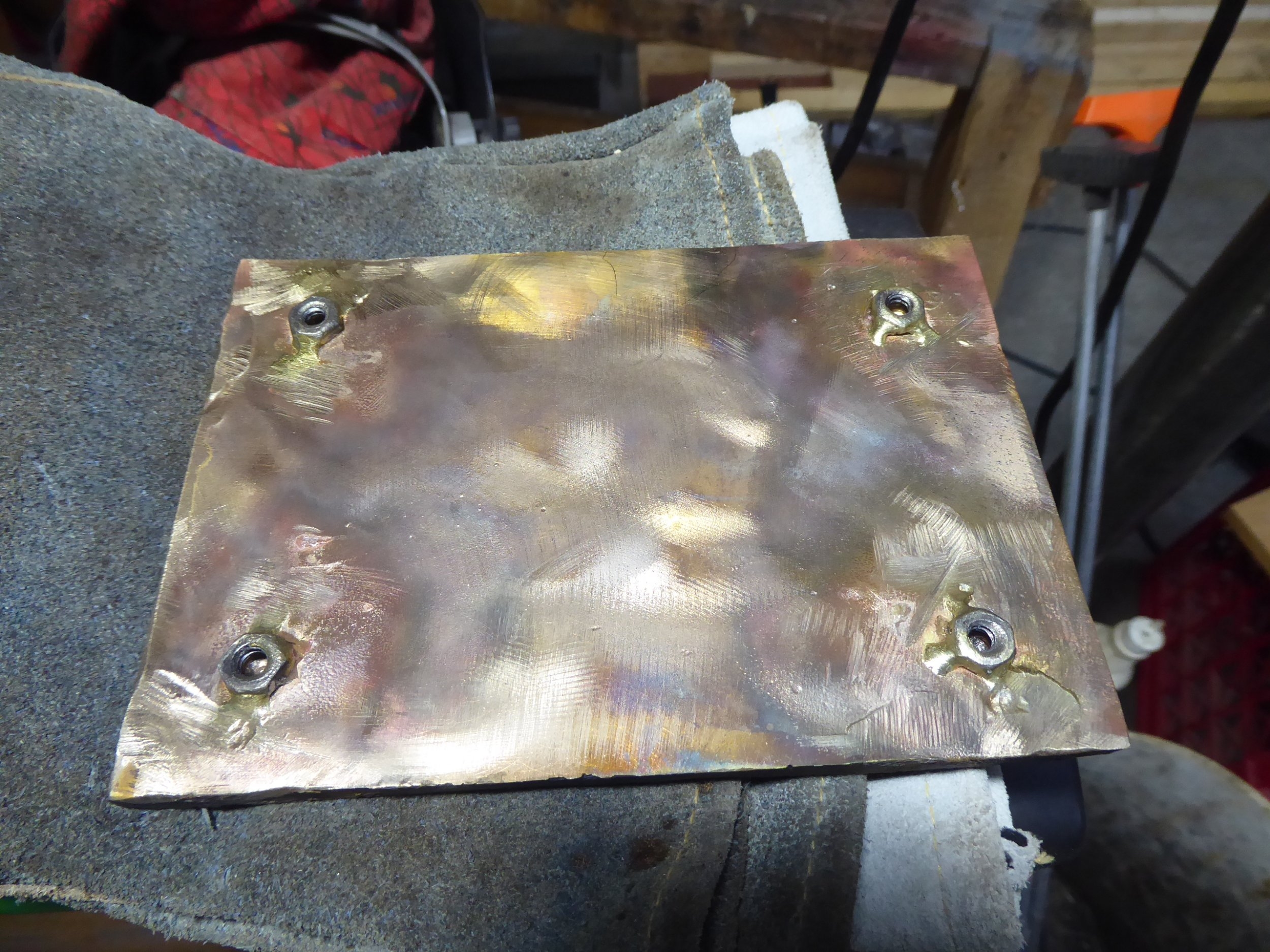

I have a neighbor friend who is an artist that works in bronze. Every once in a while he will bring over a bronze plaque and ask me to weld 10-24 nuts on the back so he can mount them in a wood frame he makes by routing out a recess. So far I have done about 10 of these, a couple at a time. I have a stick welder and an O/A set and I am just a door yard welder. I don't have much chance to experiment on a method and am nervous about screwing up his piece. So far the best method I have found is the O/A set and 1/16 bronze flux coated rod and catch the nut on 3 sides. I put a stainless screw in the nut an set it in the marker hole he drills after I grind the area off a little (Pic not ground off).

As soon as I catch one side I remove the screw. If I don't the screw gets stuck with flux or bronze wicks to it and I have to grind the nut off when I twist off the screw. When I braze the other sides with the threads open they tend to get crudded up. Most times I can fix it with a bottom tap I made by cutting off a standard tap. The job doesn't come out beautiful but it's best I can do and he is happy.

I keep thinking there must be an easier way and am looking for suggestions. Thanks !

gg

As soon as I catch one side I remove the screw. If I don't the screw gets stuck with flux or bronze wicks to it and I have to grind the nut off when I twist off the screw. When I braze the other sides with the threads open they tend to get crudded up. Most times I can fix it with a bottom tap I made by cutting off a standard tap. The job doesn't come out beautiful but it's best I can do and he is happy.

I keep thinking there must be an easier way and am looking for suggestions. Thanks !

gg

Last edited: