After thinking about it, I should not have taken the valve apart that far. I should have left the end cap and jam nut in place. I'm sure that determines the pressure of the valve. Thanks for the diagrams. My parts book does not have those pages. I'm glad they list the pressures on the valves. It makes sense that each function has its own valve. Dipper, boom, bucket and the swing has two. I'm assuming I could get some fittings and a pressure gauge and unhook the dipper crown line and install it on the line and momentarily dead head the pressure and adjust it to 3500psi. I just noticed that the boom valve is also 3500 psi. I'm going to take that valve off and measure the distance between the jam nut and the body of the valve and set the one I took apart to the same distance. That should get me close, then I am going to install them in opposite locations and see if and any the concerns swap between the dipper and the boom. Without a service manual it's a lot of educated guesses. If after all that and still nothing I'm thinking about checking gpm flow as K5lwq described. It very well could be a worn pump and it probably would be good to rule it out. I do not mind replacing the pump but would hate to replace it and still have the problem. Thanks for all the help. I'll post some results soon.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?

/ Ford 555C boom/dipper

#21

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,677

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

It comes down to flow vs pressure, doesn't it.

No matter what kind of hydraulic pump a tractor uses, all a pump can do is make the fluid flow. Pressure comes about when that flow is blocked. If there is no resistance, there is no pressure and the hydraulic fluid flows from the sump to the pump and back again unimpeded.

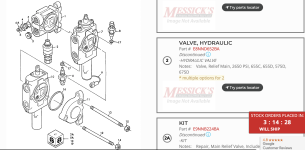

We all know those things, But in the parts text next to the parts photos in post #20 we see relief valves with settings ranging from nearly 3000 psi all the way up to 4600 psi !

Seeing back hoe relief vaves with higher than expected relief pressures leads to some questions.

What happens when a pump is deadheaded? What is happening inside the pump?

Can a tractor hydraulic pump really put 3500 to 4600 psi on that backhoe relief valve?

What makes a new pump perform differently from a worn one? What is wearing?

enjoy,

rScotty

No matter what kind of hydraulic pump a tractor uses, all a pump can do is make the fluid flow. Pressure comes about when that flow is blocked. If there is no resistance, there is no pressure and the hydraulic fluid flows from the sump to the pump and back again unimpeded.

We all know those things, But in the parts text next to the parts photos in post #20 we see relief valves with settings ranging from nearly 3000 psi all the way up to 4600 psi !

Seeing back hoe relief vaves with higher than expected relief pressures leads to some questions.

What happens when a pump is deadheaded? What is happening inside the pump?

Can a tractor hydraulic pump really put 3500 to 4600 psi on that backhoe relief valve?

What makes a new pump perform differently from a worn one? What is wearing?

enjoy,

rScotty

Today I took the valve back out for the dipper and took the valve out for the boom. They are both rated at3500psi. I checked the measurement between the jam nut and the body of the valve for the boom and compared it to the dipper valve I took apart. They were the same. So, I'm hoping I got adjusted correctly. I installed them in opposite locations hoping the problem would move from the dipper to the boom, but it did not. So, I'm thinking the valves are ok. After cleaning up my mess I took off a line for the dipper cylinder and put it in a 5-gallon bucket market at 2 gallons. I ran the tractor close to full throttle, help the stick for that particular dipper control for 4 seconds. After the oil settled it was just slightly over my 2-gallon marks. 31gpm flow equals .51 gallons a second. So basically 2 gallons every 4 seconds. It right at the spec. So, the pump and valves are good. I'm assuming it has to be something inside the valve block. It's like excess flow from the dipper is being dumped to the return.

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,677

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

All real interesting and I think you are on the right track. How did you find out they were both rated at 3500 psi? Does that mean your Ford shop manual arrived?

Swapping those two sounds like a good idea to find the problem. You might want to swap others as well. Isn't there still two additional relief valves - possibly with an anti-cavitation circuit in each - on each spool valve? It might be any of those.

As to deadheading with a pressure gauge, first you need to know what the relief pressure is on the main output of the hydraulic pump. You may not be able to reach 3500 psi by deadheading the pump. Hydraulic pumps are often set by the system relief valve to be slighty below 3000 psi to comply with the working strength of the most common grade of industrial hydraulic fittings and hoses - but Ford may have used higher grade fittings & hoses....which would allow higher relief settings. Hydraulic pump pressure in a deadheaded system without a relief valve is theoretically infinite, but in reality it is set by the main system relief valve and eventually by wear in the pump. I'd be surprised if the main relief is to be set over 2950 psi.... ( more commonly 2700 psi).

Congrats on checking the flow rate. I bet that was a bit of a mess! What you found fits what was expected. Pump wear doesn't have much effect on unimpeded flow rate. Wear can affect max deadhead pressure - but rarely affects it enough to make it less than the relief valve setting.

rScotty

Swapping those two sounds like a good idea to find the problem. You might want to swap others as well. Isn't there still two additional relief valves - possibly with an anti-cavitation circuit in each - on each spool valve? It might be any of those.

As to deadheading with a pressure gauge, first you need to know what the relief pressure is on the main output of the hydraulic pump. You may not be able to reach 3500 psi by deadheading the pump. Hydraulic pumps are often set by the system relief valve to be slighty below 3000 psi to comply with the working strength of the most common grade of industrial hydraulic fittings and hoses - but Ford may have used higher grade fittings & hoses....which would allow higher relief settings. Hydraulic pump pressure in a deadheaded system without a relief valve is theoretically infinite, but in reality it is set by the main system relief valve and eventually by wear in the pump. I'd be surprised if the main relief is to be set over 2950 psi.... ( more commonly 2700 psi).

Congrats on checking the flow rate. I bet that was a bit of a mess! What you found fits what was expected. Pump wear doesn't have much effect on unimpeded flow rate. Wear can affect max deadhead pressure - but rarely affects it enough to make it less than the relief valve setting.

rScotty

No, I have not received the manual yet. In the parts diagram in the description of the part it states what the pressures are. Also, when I took the two valves out there is an aluminum band around the body of the valves and it has the pressure stamped into it. The boom and dipper are 3500 psi, the bucket is 3000psi and the swing valves are 2700psi. All these valves have at least two valves built into them, possibly three. There also is a pressure relief valve of 4600psi. This valve is a simple one valve pressure relief. This might be an overall system pressure relief valve. Odd thing is this valve in on the oil input side of the valve block assembly. I guess it really does not matter where the valve is at in the system as long as it dumps the pressure to the return if it reaches 4600psi. Something I just noticed if you look at the diagram you posted on page 2. Mines is the picture without the power beyond, look at number 24 and 25. It is a poppet valve and spring and it is all the way on the left side of the valve block, the return end. That spool valve happens to be the left stabilizer.All real interesting and I think you are on the right track. How did you find out they were both rated at 3500 psi? Does that mean your Ford shop manual arrived?

Swapping those two sounds like a good idea to find the problem. You might want to swap others as well. Isn't there still two additional relief valves - possibly with an anti-cavitation circuit in each - on each spool valve? It might be any of those.

As to deadheading with a pressure gauge, first you need to know what the relief pressure is on the main output of the hydraulic pump. You may not be able to reach 3500 psi by deadheading the pump. Hydraulic pumps are often set by the system relief valve to be slighty below 3000 psi to comply with the working strength of the most common grade of industrial hydraulic fittings and hoses - but Ford may have used higher grade fittings & hoses....which would allow higher relief settings. Hydraulic pump pressure in a deadheaded system without a relief valve is theoretically infinite, but in reality it is set by the main system relief valve and eventually by wear in the pump. I'd be surprised if the main relief is to be set over 2950 psi.... ( more commonly 2700 psi).

Congrats on checking the flow rate. I bet that was a bit of a mess! What you found fits what was expected. Pump wear doesn't have much effect on unimpeded flow rate. Wear can affect max deadhead pressure - but rarely affects it enough to make it less than the relief valve setting.

rScotty

Checking flow was easier than I thought and without spilling a drop. I took a 5 gallon bucket and measured 2 gallons and marked it, cut a small hole in a lid and snapped the lid on, tired the bucket to the boom, unthreaded a dipper hose and put the hose into the hole. I had someone hold the hose so it would not come out of the hole but did not need to after all, ran it at around 2000rpm pulled the lever and timed it for 4 seconds and got a little over 2 gallons. I was surprised how easy it was.

I am right in thinking if it has proper flow there is no reason to check pressure with a gauge? it should have pressure, or not if something is dumping pressure to the return circuit. Looking at the valve block from left to right is stabilizer-dipper-bucket-swing-boom-stabilizer.

When using the dipper no other functions work but everything seems to work individually. The dipper is almost on the left end which happens to be the return side which happens to be where that poppet valve is.

jshwhite

Gold Member

Late to the party here but have read the thread with interest, as I had a similar issue on my Case 580C. I have a lot of seat time on various digging machines and am used to double and triple functioning, but I couldn't get the old Case to do it - I'd have the boom moving and add a little dipper or bucket curl and the boom would stop. I spent $500 and had a hydraulic shop go through the entire valve block (he said over 100 o-rings replaced!), and it helped some but not much.

I was told that the difference is between the open center and closed center hydraulic system. Most of the newer equipment I'd run was closed center, but these older hoes are open center. I found it's a lot more feathering to double/triple function, but once I got the hang of it it works pretty well.

Here's the link to that thread. Case backhoe controls acting weird

Not saying that's the situation with your 555, but something to keep in mind.

I was told that the difference is between the open center and closed center hydraulic system. Most of the newer equipment I'd run was closed center, but these older hoes are open center. I found it's a lot more feathering to double/triple function, but once I got the hang of it it works pretty well.

Here's the link to that thread. Case backhoe controls acting weird

Not saying that's the situation with your 555, but something to keep in mind.

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,677

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

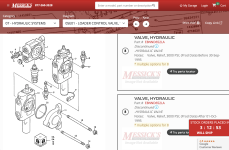

Look at the attached picture of the loader control valve. The loader valve is where most tractors with a loader has its main system relief valve, because it is the very first thing connected to the pressure output side of the hydraulic pump. Note that it has a max of liess than 3000 psi - just as we thought yesterday this tractor uses common hydraulic grade components, and so the main relief valve absolutely controls the pump output. Pump Output will never be more than roughly 3000 psi minus a factor of safety - often the FoS is 10%, but here it seems a bit higher. That's good, and saves you and Ford major money.No, I have not received the manual yet. In the parts diagram in the description of the part it states what the pressures are. Also, when I took the two valves out there is an aluminum band around the body of the valves and it has the pressure stamped into it. The boom and dipper are 3500 psi, the bucket is 3000psi and the swing valves are 2700psi. All these valves have at least two valves built into them, possibly three. There also is a pressure relief valve of 4600psi. This valve is a simple one valve pressure relief. This might be an overall system pressure relief valve. Odd thing is this valve in on the oil input side of the valve block assembly. I guess it really does not matter where the valve is at in the system as long as it dumps the pressure to the return if it reaches 4600psi.

For now, ignore the 4600 psi relief. It is especially specific only to that function on the backhoe. We can get around to the physics of it when we get deeper into the hydraulics. Only a portion of that pressure is from the hydraulic pump; the remainder of the extra pressure over (3000-SoF) psi is mechanically generated by the movement of the backhoe.

Nice catch. That is the backhoe main pressure CHECK VALVE. It is what keeps the hoe from dangerously collapsing if a hose breaks.Something I just noticed if you look at the diagram you posted on page 2. Mines is the picture without the power beyond, look at number 24 and 25. It is a poppet valve and spring and it is all the way on the left side of the valve block, the return end. That spool valve happens to be the left stabilizer.

If you look closely, that check valve is within the common pressure plenum defined by the O ring between each spool valve body. So like many things hydraulic it could be anywhere within that plenum; it just happens to be physically located on the left stabilizer. I doubt that it is the problem, since that poppet works the reverse of a relief valve and should normally be open, not closed.

No. That is not right. Let's reboot your brain. When you think PRESSURE, think back pressure.....and when you think FLOW, think flow rate. They are opposites.I am right in thinking if it has proper flow there is no reason to check pressure with a gauge? it should have pressure, or not if something is dumping pressure to the return circuit. Looking at the valve block from left to right is stabilizer-dipper-bucket-swing-boom-stabilizer.

When using the dipper no other functions work but everything seems to work individually. The dipper is almost on the left end which happens to be the return side which happens to be where that poppet valve is.

That may help you to realize that Pressure and Flow Rate are related, but the relationship is inverse .... Flow rate is at maximum when pressure is at minimum, & vice versa. When you measured flow, it was with the system unhooked so that there was almost no back pressure at all. So naturally you measured full flow rate.

Pump wear has almost no effect on flow rate. Look at how any pump is built. It gets its flow from trapping fluid and moving it. Wear doesn't affect the volume of the fluid traps very much.

Pump wear can slightly affect how much pressure a pump can develop because wear allows the trapped fluid to circulate within the pump. But it takes a huge amount of wear to drop pump pressure below the relief valve setting. You won't go wrong considerng that the relief valve is what sets the system pump pressure on an open center hydraulic system - even one with an old worn pump. Hydraulic systems are designed to continually balance (back) pressure and flow rate.

If you really wanted to measure the performance of a hydrualic pump you use a fairly rare and expensive shop tool mis-named as a "flowmeter".

It really should be called a "pressure vs flow comparison meter". It measures flow as it adds restriction and the result is a nonlinear graph called a pump performance graph. You can find them all over. Flow on one axis and pressure head on the other. Multiply them together and divide by a constant to get the hydraulic HP of the pump !

rScotty

Last edited:

Dman1981

Gold Member

- Joined

- Jul 28, 2023

- Messages

- 420

- Tractor

- Kubota bx2200

Those are circuit reliefs or protection reliefs in case you push or pull something to hard cylinder will not bend rod or break something you have to adjust them by putting a hand pump on fitting into valve and pump it up till it goes off at pressure specified

adjust accordingly

adjust accordingly

Hi, It's been a week and I do not have any new updates yet. Just been too busy with work. My next step is to talk with the person I spoke to on the phone that operated a 555 for years. They sold it with 15k hours. I think I can better understand him if we were talking in person. Thanks rScotty and Dman1981. What you both described makes sense. I'm still waiting on a manual. Knowing the hydraulic routing from the pump would help greatly. rScotty, you mentioned in an earlier post about a relief valve dumping pressure because of something stuck inside of it. If the pump output does go to the loader valve first, which makes sense, I could have something foreign stuck in the main relief valve. Rememer I am missing the screen inside the hydraulic tank. The pump output does head towards the rear of the tractor on the right side and that is where the loader control is at and I'm assuming from there it heads back to the backhoe. It does not make sense to go to the backhoe first and then back up front to the loader control. If it did it would have to go back to the backhoe again to catch the return. I would think a stuck valve anywhere could possible bypassd pressure. I'm thinking dirt from the tank would possibly get stuck in the first valve it flowed to which sounds like the main pressure valve. I think the loader spool valves are behind the right-side step, which is easy to remove. I'm hoping to have the time tomorrow and maybe I can remove the main pressure valve.

Flogger

Silver Member

A bad pump might flow the required amount and it might reach the required pressure but it won't do both. That is why a flowmeter and pressure gauge are needed to get the full picture.