Hi all,

The snowblower (Cyclone) I bought is from a Canadian company (Pronovost) that mostly speaks French and I do not. The PTO drive shaft they used is Italian (Comer industries T60) although if I'm being honest I'm not sure it would matter with regard to my questions as this is my first rear PTO driven implement.

I'm trying to learn about and be diligent with the required grease maintenance and I have a lot of questions I can't figure out how to find answers to.

I attached five pictures and here are my questions.

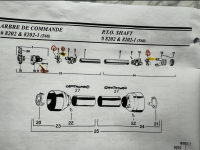

1. For the grease diagram what exactly is that saying? To me it looks like there are several different drive shafts, is it referencing the outer cover somehow?

2. On the tractor side of the PTO shaft it looks like there might be a grease fitting on the u-joint but the location requires a 90, it looks slightly oversized so it has me guessing. Do people keep two grease guns around for straights and 90s?

3. Each side of the outer plastic housing looks like it has a grease fitting - is that really what it's for, and why?

4. How do I disassemble this thing, and I am assuming I need to regularly dissasemble to apply the grease to some parts? I included a diagram from the snowblower manual but I'm still very confused.

Thank you

The snowblower (Cyclone) I bought is from a Canadian company (Pronovost) that mostly speaks French and I do not. The PTO drive shaft they used is Italian (Comer industries T60) although if I'm being honest I'm not sure it would matter with regard to my questions as this is my first rear PTO driven implement.

I'm trying to learn about and be diligent with the required grease maintenance and I have a lot of questions I can't figure out how to find answers to.

I attached five pictures and here are my questions.

1. For the grease diagram what exactly is that saying? To me it looks like there are several different drive shafts, is it referencing the outer cover somehow?

2. On the tractor side of the PTO shaft it looks like there might be a grease fitting on the u-joint but the location requires a 90, it looks slightly oversized so it has me guessing. Do people keep two grease guns around for straights and 90s?

3. Each side of the outer plastic housing looks like it has a grease fitting - is that really what it's for, and why?

4. How do I disassemble this thing, and I am assuming I need to regularly dissasemble to apply the grease to some parts? I included a diagram from the snowblower manual but I'm still very confused.

Thank you