dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 13,627

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

Yeah it is more of it not collecting water inside and making a rust mess or filling up and freezing. But I also wanted to make a tool box for my tractor that is pretty much watertight. So... it is a skill I am trying to learn with sheet metal and tubing. I hate when I pick up something that has been sitting outside and I turn it and rust colored water pours out on my shoe. Just don't like water traps!Watertight is no problem, it's a pretty quick pulse, about as quick as you can work that trigger finger. I have never quantified it but guessing from memory it's about 2/3 on, 1/3 off.

Why watertight, does it hold liquid? Or just to exclude water so it doesn't leak rust stains or fill with ice? You can do that with paint if the weld is decent.

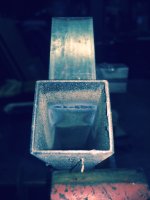

This pic is 1" x 1" x .065" (=16ga) pulsed with .030 wire. You can make it a little tighter with .023 wire. I think you'll pick it up pretty fast.

Using the exact tubing you mentioned, building a greenhouse bench, I was occasionally getting blow out with .030 wire. And dang it, I just got back from HD and forgot the .023 wire!!! :mur: