IHDiesel73L

Silver Member

- Joined

- May 13, 2010

- Messages

- 167

I was searching around for plans for a smaller pole barn with a large gambrel roof loft and a thread about something similar on another forum:

http://www.mytractorforum.com/showthread.php?t=42443

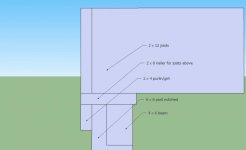

He hasn't logged on in over a year so I don't think he's around anymore, but what I did was study his pictures to try to copy the design. He did mention that his would have to pass code-mine would as well since I live in New Jersey, but from what I heard the inspectors are very willing to work with a homeowner that at least has an idea of what they're doing and how to do it the right way. This is the most helpful picture from the thread:

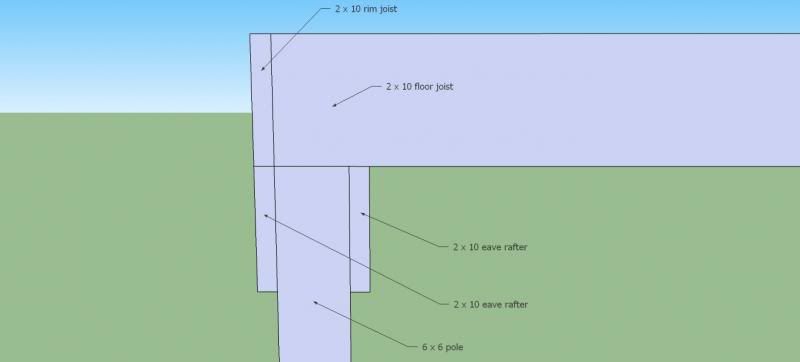

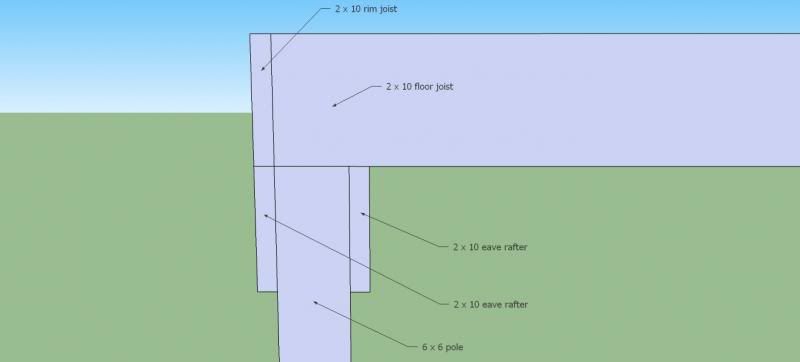

As far as the pole barn portion itself that's all pretty standard, 6 x 6 poles (though I've read that 4 x 4s are adequate for an 8' wall-can anyone comment on that?), 8' spacing, girts 2' OC, etc... Where my design starts to deviate is the second story. It looks as though he used 2 x 6s for his floor joists. I plan on using 2 x 10s. The reason is because as you can see he has a center support girder which I don't want in mine. I looked up the maximum span for a #2 Doug Fir 2 x 10 16" OC and it gives me 14' - 11". The span between my inside eave rafters (I think that's what they're called?) will be 14' - 7", so I should be good there. I'm not sure of the best way to tie in the floor platform up top to the poles though. Obviously I'll nail each joist into all four eave rafters, but I'm thinking that there must be some better way. Here are two different details:

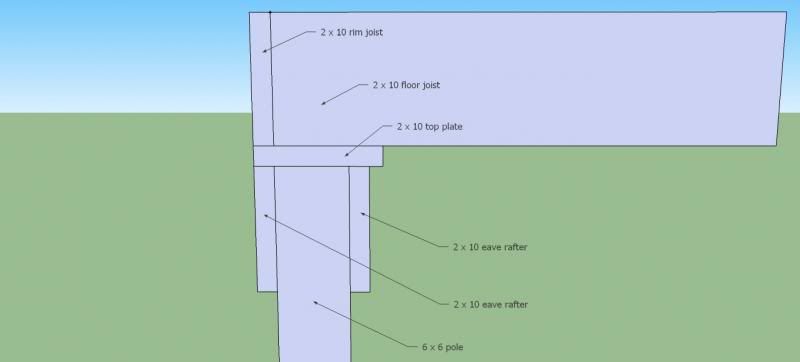

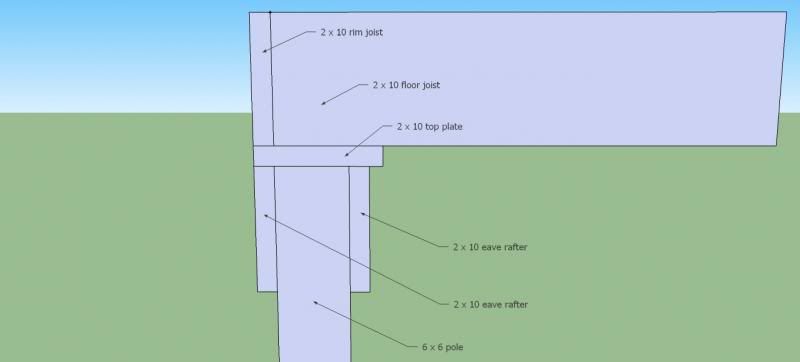

Now the same idea but with a 2 x 10 top plate over the poles as a more substantial nailer for the joists:

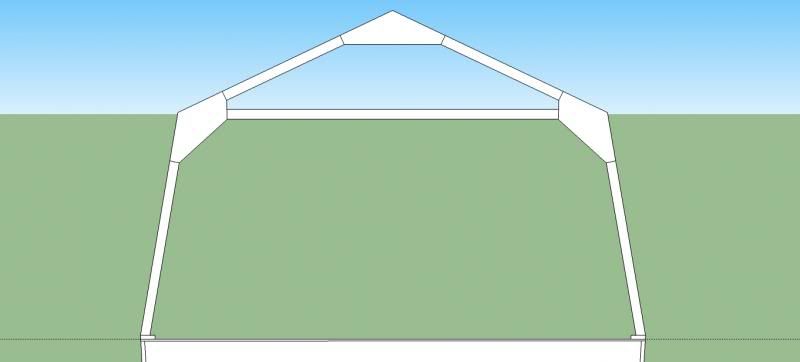

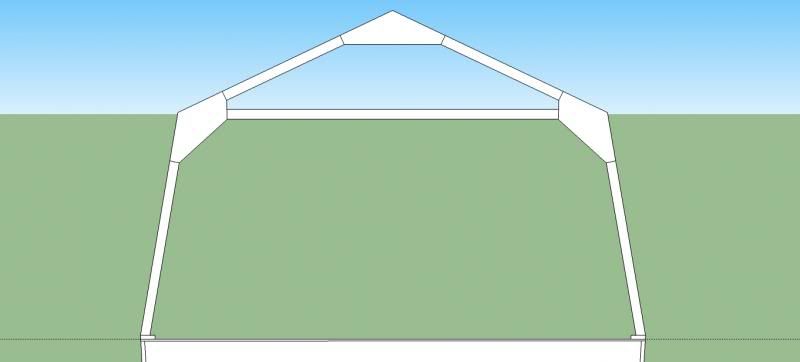

Is one really better than the other? Now onto the loft. I want to use a gambrel truss in order to get the most out of the loft space. I'll be using it for a lot of out of season storage so that I can keep the floor space of the barn for equipment and workspace. Again, I basically copied JDA's design from the pictures-here's what I came up with:

It's pretty simple and uses 2 x 4s and plywood gussets. From what I've heard homeowners are allowed to design their own trusses and the inspector will offer guidance if they think it's needed. This is going to be a pretty simple barn-compacted stone dust floor, sliding door, etc... Also I'll be using steel siding and roofing, so there will be girts nailed across the trusses as well. I welcome any criticism or thoughts on the design.

http://www.mytractorforum.com/showthread.php?t=42443

He hasn't logged on in over a year so I don't think he's around anymore, but what I did was study his pictures to try to copy the design. He did mention that his would have to pass code-mine would as well since I live in New Jersey, but from what I heard the inspectors are very willing to work with a homeowner that at least has an idea of what they're doing and how to do it the right way. This is the most helpful picture from the thread:

As far as the pole barn portion itself that's all pretty standard, 6 x 6 poles (though I've read that 4 x 4s are adequate for an 8' wall-can anyone comment on that?), 8' spacing, girts 2' OC, etc... Where my design starts to deviate is the second story. It looks as though he used 2 x 6s for his floor joists. I plan on using 2 x 10s. The reason is because as you can see he has a center support girder which I don't want in mine. I looked up the maximum span for a #2 Doug Fir 2 x 10 16" OC and it gives me 14' - 11". The span between my inside eave rafters (I think that's what they're called?) will be 14' - 7", so I should be good there. I'm not sure of the best way to tie in the floor platform up top to the poles though. Obviously I'll nail each joist into all four eave rafters, but I'm thinking that there must be some better way. Here are two different details:

Now the same idea but with a 2 x 10 top plate over the poles as a more substantial nailer for the joists:

Is one really better than the other? Now onto the loft. I want to use a gambrel truss in order to get the most out of the loft space. I'll be using it for a lot of out of season storage so that I can keep the floor space of the barn for equipment and workspace. Again, I basically copied JDA's design from the pictures-here's what I came up with:

It's pretty simple and uses 2 x 4s and plywood gussets. From what I've heard homeowners are allowed to design their own trusses and the inspector will offer guidance if they think it's needed. This is going to be a pretty simple barn-compacted stone dust floor, sliding door, etc... Also I'll be using steel siding and roofing, so there will be girts nailed across the trusses as well. I welcome any criticism or thoughts on the design.