Reading Inspector507's posts about the rear remote on a TC18, reminded me that I really need to get cranking one of these days on an attachment I got with my tractor but have not yet used.

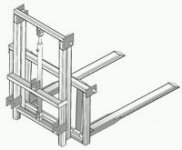

It's a bale lifter that attaches to the 3 point hitch, and has a hydraulic lift that will lift the bale -- or whatever -- even higher. It was sold as a bale lifter, because the forks are more square than a forklift, and there is a bale spear near the top. The bale spear is removable, and the forks can be used as a forklift. That's how I plan to use it. I don't have a picture of it; it's similar to the CadLift shown in the attachment.

I got it in a simple sweetener deal. The dealer and I were close in our negotiations, but I was looking for something more. I mentioned a need for pallet forks; I was thinking about something that attached to the bucket. I have a need to unload pallets from time to time from the back of semi trailers, pallets that weigh 400# or so.

The owner of the dealership was nearby and overheard us, and mentioned the 3 point hydraulic lift they had bought as a new item, but never sold. It was brand new, but had been sitting around outside for a couple of years, and was a bit ragged looking. They looked it up, and said the list price was around $1,000. If I agreed to buy the tractor, they'd throw it in.

It was designed for category 2, but I can install cat 1 pins and turn them to the inside and it will fit my 3 point very well. The unit weighs around 400#, but I have 1265# lift capacity on the 3 point, so there will be enough capacity to lift the unit and my pallets.

The technique is to lower the lift and lower the 3 point, run under the pallet, provide the initial lift with the 3 point, then continue lifting with the hydraulic cylinder on the unit. It has enough total lift to get to the floor of most semi trailers.

Initially, the dealer and I figured that I could run the unit's hydraulic cylinder with long hoses attached to one function of the FEL. The more I thought about it, however, the more I realized that I would also need a hydraulic top link to keep the forks at the right angle as I lifted the unit.

The TC18 only has the capability of installing one rear remote; as seen on the thread about the rear remote, the clearances are pretty tight. If I install a hydraulic top link, I'd also like to install a tilt link, and also have the ability to control this fork lift without unhooking one of the FEL functions and running long hoses. So, I need a total of 3 rear remotes.

I've had some conversations about this in the past, and have been given some references, but I'm really a babe in the woods when it comes to hydraulics. My guess is that I need to add the rear remote, then add some kind of power beyond setup, but when I go to the various links I've been given, it's all Greek to me.

So, here are my questions. First, has anyone ever seen or used a rig similar to what I have? I've really looked, and I can't find anything like it on the 'net, except the CadLift I've pictured. There is no manufacturer's plate on my unit. It has a capacity plate, but no Mfr.

Second, now that I've seen how to hook up the rear remote, thanks to Inspector507, can anyone point me to a kit or specific list of parts for installing a power beyond setup and get two more rear remotes? I'm not too worried about flow rates; while the TC18 has a relatively low flow rate it's always had enough for all my jobs, and I'm willing to use the controls one at a time. What I really need is a parts list -- buy "this from this outfit" and "that from the other", and it will work.

This unit makes a lot of sense for me if I can get it working, because I don't want the semis using my driveway -- not enough turn-around room. I'll unload them on the county road, then carry the pallets about 700' to the barn. The stability of having them on the back is very reassuring to me.

It's a bale lifter that attaches to the 3 point hitch, and has a hydraulic lift that will lift the bale -- or whatever -- even higher. It was sold as a bale lifter, because the forks are more square than a forklift, and there is a bale spear near the top. The bale spear is removable, and the forks can be used as a forklift. That's how I plan to use it. I don't have a picture of it; it's similar to the CadLift shown in the attachment.

I got it in a simple sweetener deal. The dealer and I were close in our negotiations, but I was looking for something more. I mentioned a need for pallet forks; I was thinking about something that attached to the bucket. I have a need to unload pallets from time to time from the back of semi trailers, pallets that weigh 400# or so.

The owner of the dealership was nearby and overheard us, and mentioned the 3 point hydraulic lift they had bought as a new item, but never sold. It was brand new, but had been sitting around outside for a couple of years, and was a bit ragged looking. They looked it up, and said the list price was around $1,000. If I agreed to buy the tractor, they'd throw it in.

It was designed for category 2, but I can install cat 1 pins and turn them to the inside and it will fit my 3 point very well. The unit weighs around 400#, but I have 1265# lift capacity on the 3 point, so there will be enough capacity to lift the unit and my pallets.

The technique is to lower the lift and lower the 3 point, run under the pallet, provide the initial lift with the 3 point, then continue lifting with the hydraulic cylinder on the unit. It has enough total lift to get to the floor of most semi trailers.

Initially, the dealer and I figured that I could run the unit's hydraulic cylinder with long hoses attached to one function of the FEL. The more I thought about it, however, the more I realized that I would also need a hydraulic top link to keep the forks at the right angle as I lifted the unit.

The TC18 only has the capability of installing one rear remote; as seen on the thread about the rear remote, the clearances are pretty tight. If I install a hydraulic top link, I'd also like to install a tilt link, and also have the ability to control this fork lift without unhooking one of the FEL functions and running long hoses. So, I need a total of 3 rear remotes.

I've had some conversations about this in the past, and have been given some references, but I'm really a babe in the woods when it comes to hydraulics. My guess is that I need to add the rear remote, then add some kind of power beyond setup, but when I go to the various links I've been given, it's all Greek to me.

So, here are my questions. First, has anyone ever seen or used a rig similar to what I have? I've really looked, and I can't find anything like it on the 'net, except the CadLift I've pictured. There is no manufacturer's plate on my unit. It has a capacity plate, but no Mfr.

Second, now that I've seen how to hook up the rear remote, thanks to Inspector507, can anyone point me to a kit or specific list of parts for installing a power beyond setup and get two more rear remotes? I'm not too worried about flow rates; while the TC18 has a relatively low flow rate it's always had enough for all my jobs, and I'm willing to use the controls one at a time. What I really need is a parts list -- buy "this from this outfit" and "that from the other", and it will work.

This unit makes a lot of sense for me if I can get it working, because I don't want the semis using my driveway -- not enough turn-around room. I'll unload them on the county road, then carry the pallets about 700' to the barn. The stability of having them on the back is very reassuring to me.