dirtworksequip

Veteran Member

- Joined

- Jun 3, 2006

- Messages

- 1,463

- Location

- Wheeling, WV

- Tractor

- 2006 JD 3520 w/cab & 300CX loader. 1995 JD 870 w/440 loader & 8b backhoe.JD 455 w/54" mower deck.

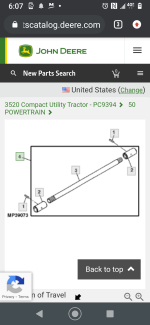

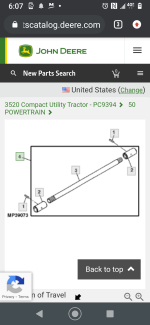

My 3520 keeps kicking out of 4wheel drive. I found the problem, but have not determined what the fix is. Seems the splined slip collar moves and lets the shaft slip out of position far enough that the 4wheel drive doesn't work until i crawl under the tractor ann physically move the shaft so it engages.

I know there is a roll pin through each of the 2 slip collars. What is going on that my shaft is moving too much and disengages?

Is there any adjustment on the shaft for end play?

Any help would be appreciated.

9

I know there is a roll pin through each of the 2 slip collars. What is going on that my shaft is moving too much and disengages?

Is there any adjustment on the shaft for end play?

Any help would be appreciated.

9