Squidbait

Bronze Member

Greetings gentleman,

I had a couple of questions about the John Deere 430 Lawn Tractor I use to mow the yard for my church. The church bought the tractor new back in the late 1980's or early 1990's. I was mowing the church property the other day and plop! the right front wheel spindle broke into (basically the wheel came off). The spindle rod broke right where rod intersects the flat metal plate (that extends out to attach to the steering rod). The actual rod broke into. I hate to say this, but the left front spindle broke off last fall in the same spot on the spindle. Last fall we ordered a replacement spindle for our tractor - looking up the serial number on TractorData.com the tractor appears to be a 1992 model (the last year they where made). When our replacement spindle arrived it didn't fit - it was roughly 020 to .030 of an inch too large in diameter. Our John Deere dealer ordered another spindle for an earlier make of the 430 and that spindle fit perfectly. What I can't figure out is why the tractor I use (if it is a 1992 model) takes parts to fit an earlier version of the 430?

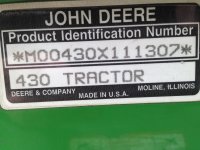

Here is the a picture of the actual serial number of the 430 I mow with.

Maybe some body can tell me if I am reading the serial number incorrectly or if the chart on TractorData.com is incorrect. We got the left front spindle replaced last year when it broke - the parts were available. We checked with our John Deere Dealer Tuesday and they told us that only one of the two makes of 430 front wheel spindle is now available. My concern is if the available spindle is the one that does not fit. What options would we have to replace or repair the broken spindle? I personally do not know any machinists or welders. If the part was welded my guess is that some of the existing material would have to be removed (machined off) to create a clean surface for welding. Plus, how does a person weld a part that is a 1 inch thick (diameter) solid steel? Maybe that is easy (I don't know. I'm not a welder.)

Any suggestions or information would be greatly appreciated.

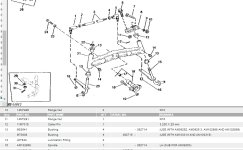

Below are a couple of pictures that I took last year that may help you visualize the area(s) where both spindles broke.

One quick comment: in the picture above that shows the actual place where the spindle broke - in the light colored area on the left of the spindle you can actually see the grain structure of the metal. The darker colored on the right of the spindle is fairly smooth with slightly raised "ripples" - no metal grain structure is visible (a shearing of the metal?). Both broken wheel spindles appear this way which puzzles me. To me I would think the grain structure would be visible across the entire cross section of this broke metal part. Any idea why this appear the way it does?

I had a couple of questions about the John Deere 430 Lawn Tractor I use to mow the yard for my church. The church bought the tractor new back in the late 1980's or early 1990's. I was mowing the church property the other day and plop! the right front wheel spindle broke into (basically the wheel came off). The spindle rod broke right where rod intersects the flat metal plate (that extends out to attach to the steering rod). The actual rod broke into. I hate to say this, but the left front spindle broke off last fall in the same spot on the spindle. Last fall we ordered a replacement spindle for our tractor - looking up the serial number on TractorData.com the tractor appears to be a 1992 model (the last year they where made). When our replacement spindle arrived it didn't fit - it was roughly 020 to .030 of an inch too large in diameter. Our John Deere dealer ordered another spindle for an earlier make of the 430 and that spindle fit perfectly. What I can't figure out is why the tractor I use (if it is a 1992 model) takes parts to fit an earlier version of the 430?

Here is the a picture of the actual serial number of the 430 I mow with.

Maybe some body can tell me if I am reading the serial number incorrectly or if the chart on TractorData.com is incorrect. We got the left front spindle replaced last year when it broke - the parts were available. We checked with our John Deere Dealer Tuesday and they told us that only one of the two makes of 430 front wheel spindle is now available. My concern is if the available spindle is the one that does not fit. What options would we have to replace or repair the broken spindle? I personally do not know any machinists or welders. If the part was welded my guess is that some of the existing material would have to be removed (machined off) to create a clean surface for welding. Plus, how does a person weld a part that is a 1 inch thick (diameter) solid steel? Maybe that is easy (I don't know. I'm not a welder.)

Any suggestions or information would be greatly appreciated.

Below are a couple of pictures that I took last year that may help you visualize the area(s) where both spindles broke.

One quick comment: in the picture above that shows the actual place where the spindle broke - in the light colored area on the left of the spindle you can actually see the grain structure of the metal. The darker colored on the right of the spindle is fairly smooth with slightly raised "ripples" - no metal grain structure is visible (a shearing of the metal?). Both broken wheel spindles appear this way which puzzles me. To me I would think the grain structure would be visible across the entire cross section of this broke metal part. Any idea why this appear the way it does?