gwdixon

Elite Member

Update:

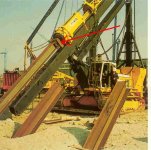

A spark test seemed to indicate that the piece is cast steel (I hope!). So I "V'ed" out the break from both sides to get a 100% weld.

Then heated it with a propane grass burner for about 10 minutes but it did not glow red. Used 3/32" 7018 at 80A for about an inch and immediately hit it with a needle scaler. Repeat, repeat, repeat.

The missing piece was filled with 1/8" 7018 at 125A but was a bit dicey (too hot). So back to 3/32" to finish.

The wear side was filled a bit with 3/32" 7018 and then topped with 5/32" Stoody 31 hardfacing at 150A (a bit cold for this rod).

The piece is currently in a bucket of sand for overnight cooling. Maybe it will come out in one piece tomorrow.

Then it will be on to grinding the critical surfaces that mate with flail mower. Since it doesn't have to be pretty the other welds may be left as is...a bit built up.

Update tomorrow. Thanks for all of the suggestions. Maybe down the line another member can benefit from this discussion as much as I have.

A spark test seemed to indicate that the piece is cast steel (I hope!). So I "V'ed" out the break from both sides to get a 100% weld.

Then heated it with a propane grass burner for about 10 minutes but it did not glow red. Used 3/32" 7018 at 80A for about an inch and immediately hit it with a needle scaler. Repeat, repeat, repeat.

The missing piece was filled with 1/8" 7018 at 125A but was a bit dicey (too hot). So back to 3/32" to finish.

The wear side was filled a bit with 3/32" 7018 and then topped with 5/32" Stoody 31 hardfacing at 150A (a bit cold for this rod).

The piece is currently in a bucket of sand for overnight cooling. Maybe it will come out in one piece tomorrow.

Then it will be on to grinding the critical surfaces that mate with flail mower. Since it doesn't have to be pretty the other welds may be left as is...a bit built up.

Update tomorrow. Thanks for all of the suggestions. Maybe down the line another member can benefit from this discussion as much as I have.