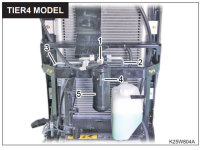

The plot thickens....... I got the expansion valve and dryer/receiver from Branson. So I pulled the roof off my tractor to see what I could find. I do not have a dryer/receiver anywhere!!!! The books show one in front of the condenser. There isn't one. You can closely follow ever inch on the line out of the condenser up to the expansion valve (exept where it goes up through the cab frame tubing to the roof area, where it is too tight for the dryer/receiver), and there just isn't one! We looked at the places it shouldn't be. There still isn't one. That may be hard to believe, but that is indeed the case. I have a call into Branson and can hopefully get an explanation of how that could be.

I did get the correct expansion valve, so we changed it. (they coat the expansion valve with a sticky, gooey black plastic wrap which makes an easy job miserable) While we had the valve out, we disconnected the lines into an out of the compressor. We blew air through the condenser, evaporator and every single line looking for line restrictions. There were none. We put the system back together and pulled a vacuum for a couple hours (It holds a vacuum fine). We charged the system. It came up to the correct pressures (22 psi on the suction, 210 psi on the high side). The expansion valve got cold on one side and hot on the other, cool air was coming out of the ducts, just like you would expect.

But after 5 minutes of running, the pressures started rising. 300+ on the high side, 35 to 40 psi on the low side. The air out of the ducts stopped being cold and the expansion valve temperatures lost its temperature differential. The high pressure line out of the compressor got very very hot. Shut it down and let it set for a half hour and cool down.

Started it up again.... Same thing.

We decided to pull the evaporator apart to see if it was plugged on the air side. (Not an easy job!) The was some dirt on the fin inlets. We blew it off and put it back together and tried it again. I also re-cleaned he condenser for the umpteenth time (it was quite clean). No change in how things worked.

It appears to me the system is loosing flow through the evaporator somehow.

One thing I thought of is maybe there is some moisture in the system, and if there is, it would accumulate at the coldest point (The discharge of the expansion valve/ inlet of the evaporator area). Possibly that moisture is freezing into ice after ity runs a while, blocking the freon flow (??) I do know that evaporating moisture out of a refrigeration system is a temperature/pressure/ time relationship. Moisture vaporizes easier at higher temperatures and lower pressures, and it takes time for that to happen. In ammonia systems we held a vacuum for 24 hrs to fully purge the system of moisture. I am holding it at a vacuum overnight now and recharge it in the morning to see if it helps, but to be honest, I don't thing it will.

I can see how a system could "work" without a dryer receiver, but it seems like it would be a very troublesome system. A I understand it, its purpose is twofold 1) remove and hold any moisture in the system and 2) serve as an accumulator for extra freon needed as the system changes temperature states. I still can't believe one was never installed.

That brings up another point. According to the book, my system should hold 2.87 lb of freon. It holds more like half that, probably because there is no dryer receiver. I have charged it several times now and that's all it takes!

It has also occurred to me that I may have some sort of problem on the controls side, but as I think through it, I don't think so.

Another thing that worries me is that we lose a tad bit of oil every time we take the system down, I don't see any way of verifying there is too little or too much oil in the system.

Anybody have better ideas of what to do next.