Xfaxman

Super Star Member

- Joined

- Feb 8, 2013

- Messages

- 13,307

- Location

- Guthrie, OK

- Tractor

- Toolcat 5610 G - Bobcat V417 - TORO+Loader

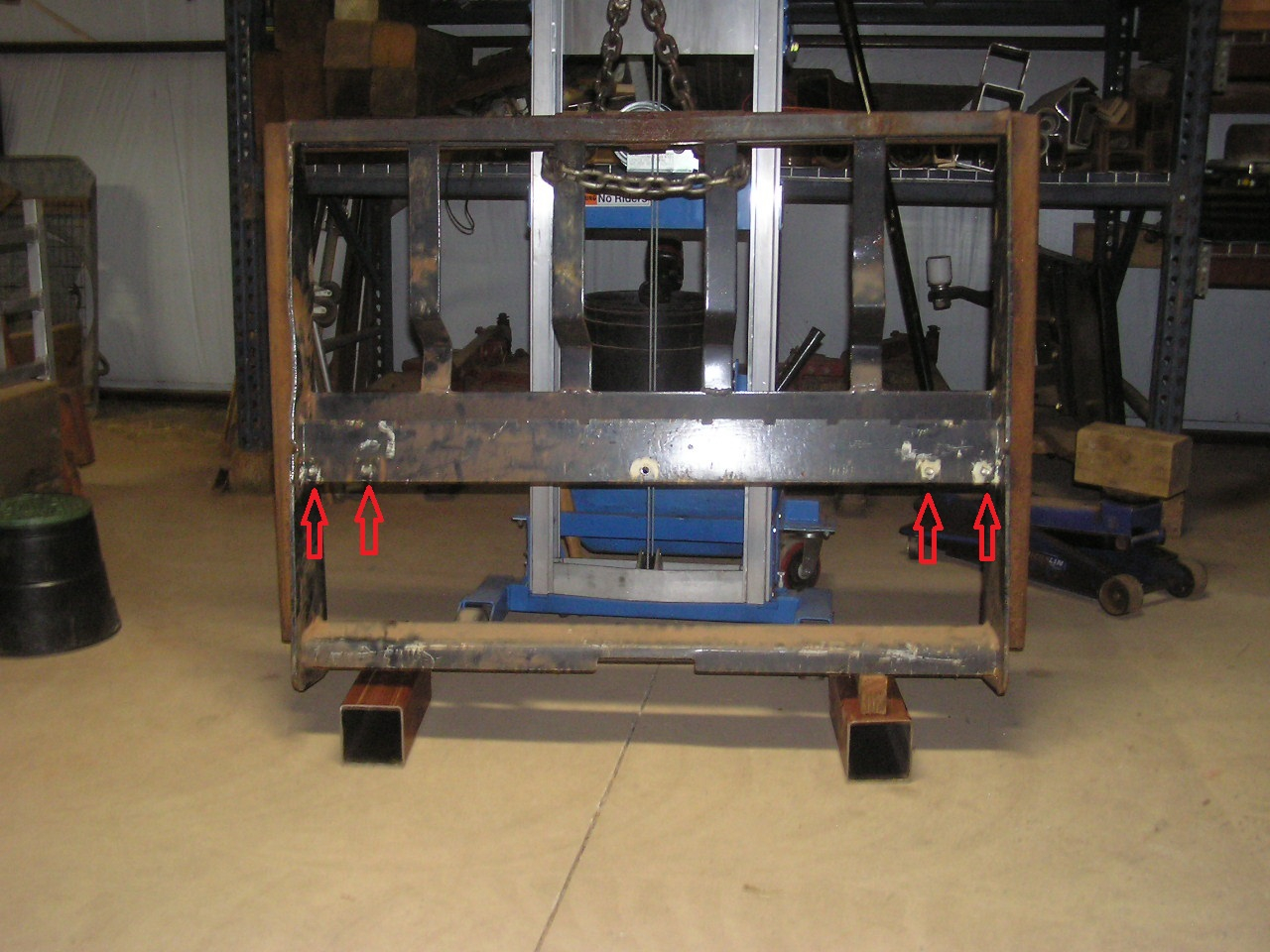

I have this old fork frame that never had forks on it:

I used it about 12 years ago to put a three point cedar tree cutter on the V417:

I do not have the tree shear now so I removed the 3 point hardware:

The frame now weighs 236 pounds:

Will be using 4 of the holes to bolt on a piece of 2-3/8" tubing:

I used it about 12 years ago to put a three point cedar tree cutter on the V417:

I do not have the tree shear now so I removed the 3 point hardware:

The frame now weighs 236 pounds:

Will be using 4 of the holes to bolt on a piece of 2-3/8" tubing:

Last edited: