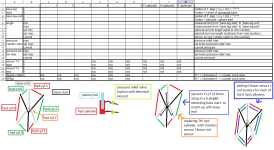

below 4 pictures are from....

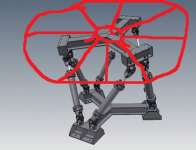

Octahedral Hexapod Mechanism (Parallel Robot) - STEP / IGES, KeyCreator, Autodesk Inventor, STL, Other - 3D CAD model - GrabCAD

playing around some, and it would seem the need for a "U joint" on cylinder end, to keep hyd hoses coming off the cylinder from getting all wrapped up, and then using a "ball joint" on the piston ends, to give a little bit more fluid motion.

==============

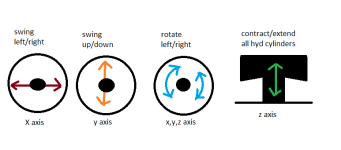

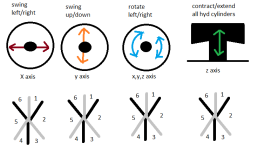

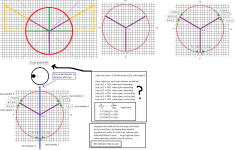

i can achieve up to 90 degree left and right (total of 180 degrees), (backhoe swinging left and right to drop spoils) but things get dicey, near that 90 degree mark, were things might get stuck and un-recoverable to swing back opposite direction. also due to placement of hyd cylinders, everything gets extend so much. (i feel more deflection / bounciness) along with total lift capacity does go down a descent amount. (the old "levers" or kids teeter totter or fulcrum comes into effect)

i can spread the hyd cylinders out (longer legs on Y) and obtain reduce degrees, of left/right, and up/down, but gain some additional rotation, and stronger lifting capacity and less chance of things binding up, if at all. some issues with cylinder end (were piston comes out) and hoses, along with sensors that still could get damaged.

the above leading me to possibly setting up extra holes / mounting options for all the hyd cylinders. spread things out far and wide, vs narrow and close to the center of the Y frames.

===============

i have looked at less than 6 cylinder setups, and more than 6 cylinder setups. and the issue always comes back to "extra play" were things would freely float in rotation mode to some extra degree. other words you have rear blade on tractor and trying to put a 5 degree crown on a gravel driveway. and the blade would rotate for example +/-5 degrees with more or less hyd cylinders. pending on setup possibly upwards of 15 +/- degrees of free play rotation.

it comes back down to a "TRIANGLE" and how the 6 cylinders are placed. that helps remove the play/slop in everything. wider the triangle (further out on the Y frames) the less play/slop there is.

the longer the hyd cylinders and pistons are (including extension / contraction of pistons) the more play/slop there is. the shorter they are the less play/slop there is

what bothers me some, is when all or some of the hyd cylinders are fully contracted. or fully extended, there is some slop/play, and additional shock loading changes

===============

i suppose if someone wanted to. they could swap out the hyd cylinders for rigid bars perhaps top/side link turnbuckles on 3pt hitches. and in playing around, i have (by accident) locked things up like a solid bar. for 1 or 2 hyd cylinders. and was interesting to say the least. it did limit my abilities but also firmed some things up. to point a possibly adding a 7th hyd cylinder or adjustable bar directly into the center of everything. possibly ball joints on each end of the center 7th unit. plan was putting a sensor rod there for rotation already, but... beefer setup *shrugs*, might help reduce "shock stress" on hyd cylinders, when dragging some of the beefer stuff, ((think stay straps, sway chains, and like for 3pt hitch, but for this, it would be the central 7th unit))

if i add the additional "positional" holes to adjust hyd cyilnders, possibly doing some chains as well to act like limiters much like sway chains / check chains do.

============

with above, it should be easy enough, to take a couple Y base frames, and use solid bars or like. and create cheap longer extensions. that could be added to either side of the unit. to either get larger offset (swing off to side of tractor), to higher lift above ground, or digging depth below ground, to setting rear blade further out behind tractor, to create more of a "motor grader" setup. i would imagine, they would act like 3pt hitches on both sides, with quick attach like ability built into them. run a couple hyd hoses, and wiring that would be needed for the electrical over hyd solenoid valves. ready set go....

================

the overall hyd cylinder bore/piston sizes.....

bore size should be able to be smaller with wall thickness a little bit thicker possibly, along with piston size might go up a little bit, much of it is due to odd angles and bending of the hyd cylinders and pistons possibly. vs your ordinary run of the mill hyd cylinder.

the pressure relief valves will need to be set for both hoses coming off the hyd cylinder.

it is looking like there will need to be 6 solenoid valves (1 per each hyd cylinder), with 1 extra for center 7th, and then 1 or 2 more for power beyond doing / rear remotes per say

==============

trying to decided if i want to just strap a rod linear sensor via pipe clamps to each hyd cylinder. or go with independent connections between the 2 Y frames.

i would need a linear sensor per hyd cylinder. due to some motions 4 cylinders are in full contract mode and 1 is barely extended out while another is some were in between fully extended/contracted,

if i go with 3 independent connections between each Y frame, and a rotation sensor via a 7th central unit. i can reduce number of sensors. from 7or8 down to 4 sensors. most likely sensors would be right at the middle / around the 7th unit if not taking the spot of the 7th unit. making it a pain to get into them (removing hyd cylinders to get at them possibly) as in getting into them to deal with trouble shooting, but more importantly to grease / lubricate things. or to adjust limiting stops.

the other issue is wires for the electrical sensors and dealing with the hyd hoses themselves coming from each hyd cylinder. that alone may play a bigger role.

==============

routing the hyd hoses....and placing electrical over hyd valves i guess i need to look more into that.

i know there is options of directly mounting stuff directly onto the hyd cylinders. but once you start moving and adjusting things about. there is not much room and more likely damage to stuff mounted directly to hyd cylinders.

back off to drawing board, to find valves and what i want for them / need from them.

EDIT: and yes, the attached pictures are misleading, once you start combining all the tilting and angling and rotation.