beyond an actual custom made doing... i do like these little small chip / boards that are stack able / interchangeability. for some of them placed on each hyd cylinder.

Microduino Wikipedia

===========

i been looking at wireless routers, what many folks have in there homes for wifi internet for there tv's, playstations, xboxes, computers, etc.... but more specifically looking at the chips in the wireless routers.

the wireless routers, give of course wifi, but also optional cat5 (rj-45 jack) cable connection if needed and or wanted, security settings for wifi, ability to adjust packet sizes, ability to route data between them if for joystick/controler is only getting a good single to one hyd cylinder wireless router chip, that wireless chip, could send data to the other hyd cylinders much like a wireless access point. there is no extra drivers (software) need per say, for SOC (software on a chip) it is already there within reason.

on some of the wireless chips offerings out there they are "open source" hardware, with dd-wrt, or some other software out there. for extra options, possibly even running a mini web app server, directly on the wireless router chip. i suppose the mini web app server, might be denoted as a mini game app server possibly. the app being, some simple calculations, adjusting the hyd cylinders to a given position. others words, turn this valve on, this valve off. possibly some simple diagnostics, or rather initialization settings. for each hyd cylinder. (setting pressure relief, over all length of hyd cylinder, and piston, along with extension/contraction info. simple notation have not received sensor input from given sensor in x time, send an error to operator (you tore something up), or send warning "pressure relief" has kicked on. i am not confident "float" and/or Trip like function, could be done directly on a wireless chip. i am sure it could, but how fast it could constantly compute the info has me, as an unknown variable.

=============

i have also looked at cell phones of all things, along with battery operated smaller size tablet computers. as being a controller itself, but initially setting up options, max pressure ratings, how much can a hyd cylinder extend/contract, (contracting so far = hitting tire for example), other words basic settings, that only need to be changed once, and/or very rarely (possibly changing settings if hooked up to a different tractor). with some cell phones having tilt / angle / acceleration / 6dof (6 degree of freedom) sensors in them. possibly, going to your cell phone, open up the app, hold finger on a given button on screen and start moving phone, and have the dog tail start moving. or... having simple left,right,up,down, tilt, angle, roll, buttons on the touchscreen, to press. to move the dog tail.

ya cell phone or a tablet computer kinda of out of there... but... say putting on a PHD (post hole digger) onto dog tail. one person on tractor, and another person as a spotter. spotter, turns on cell phone. gives a couple taps, and lines PHD up. and operator on tractor takes over. or like many folks, single person, no one else around, hoping off tractor walking in a few directions to line things up right there with cell phone. and then hoping back up on tractor to run the PHD. to say lifting something into say back of a pickup truck. but everything just not aligning up like wanted. and putting parking break on, hoping off tractor pull on a tug rope to swing things around. and open up cell phone to let things down slowly while off tractor.... ya i realize, some of things folks will do, will be pretty stupid, and i will most likely be one of them. but *shrugs*.

==============

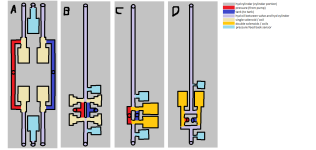

i am still looking at the master/slave joystick / dogtail combo as seen in post 21 video.

but i am also hurting, at looking at trying to figure out a way to have 0-9 buttons, menu, ok/enter, up/down arrows buttons, a LCD screen ((other words... a older school combo printer/fax/scanner/copier machine interface). a touch screen cell phone or smaller size tablet computer. little more cost. but.. a lot more options. via touch screen. plus possible a set of built in instructions / help / faq info. a touch screen cell phone or tablet computer, being able to set up a few different tractors (max pressure settings, extent / contract length of hyd cylinders), and just do a few taps with a finger and select current tractor the dog tail is hooked up to. and go. vs having to re-enter everything each and every time. possibly setting some extra settings for different implements / attachments. trying to do this through a LCD screen and 14 to 20 buttons... would be rather a large hassle. touch screen is more complex...and more likely costly. but... if i could access settings / change settings on initial starting of tractor. and then put cell phone up / tablet up, then grab a hold of joystick while on tractor....and go... go.. goo.. cell phone / tablet. possibly having "warning" sounds, (can you hear when pressure relief valves go off? have a hearing aid? ear muffs on? radio going? inside a cab?, or perhaps even voice commands. how many times have you had hands all tied up, and not an extra to go around. in getting you and tractor out of a jamb... voice commands perhaps.

==============

i am still on the line of wifi, vs wired networking / communication between everything. and only thing that going to solve it... is rough working out the code. so i actually have something i can check against. there is to many small details, that needs to be worked out.