You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Bridge Post

- Thread starter Alan L.

- Start date

- Views: 4981

More options

Who Replied?

/ Another Bridge Post

#21

BB_TX

Veteran Member

- Joined

- Jan 29, 2002

- Messages

- 1,939

- Tractor

- JD 950

Any idea what they drive across that? A really simple idea. But you would really want to know what an I beam layed on side could support.

Joe1

Platinum Member

Some of these suggestions are getting expensive. If a railroad car is too difficult to get to the creek, how about a 40' flatbed trailer truck. Haul it down there on it's wheels, remove the bogie and drop it in place on the aforementioned contrete on each side of the creek. It would also be wide enough to get a pcik=up or farm tractor across it.

Don't mean to beat a dead horse, but the reinforced steel framework is already there and it might be cheaper than building a fancy foot bridge that is only wide enough for an ATV or golf card.

Just my second dimes' worth.

Good luck.

Joe

Don't mean to beat a dead horse, but the reinforced steel framework is already there and it might be cheaper than building a fancy foot bridge that is only wide enough for an ATV or golf card.

Just my second dimes' worth.

Good luck.

Joe

Joe1

Platinum Member

I appreciate your patience with an almost duplicate post. Let us know just what you end up doing.

Joe

Joe

txdon

Super Star Member

Alan, I have seen the water gushing out of the culvert and the rocks don't budge. I can drive over the bridge with the truck or tractor. Water has risen to the top once during a flood but then goes around the bridge in a high water channel which is about 2 feet lower than than the top of the bridge. I had a bulldozer cut the (flood) channel but it could have been done with a box blade. I will attach a photo of this bridge in progress, the dirt pile was used to fill in over the culvert and was tamped in. I will take some photos of another bridge (just starting) with a larger 6' culvert upstream and post it in a few days.

Attachments

wroughtn_harv

Super Member

</font><font color="blue" class="small">( Are we talking about the same place? Just before you get to the new dump ground? They used to advertise in the local paper as Collin County Steel & Pipe.)</font>

You're right. And heck, I've known John at least ten plus years. /forums/images/graemlins/blush.gif /forums/images/graemlins/blush.gif /forums/images/graemlins/blush.gif Old age getting me again. /forums/images/graemlins/blush.gif

If I recall this bridge is only needed for a thousand pounds or so. It looks like a twenty footer will do just fine.

Here's a suggestion. I'll supply the equipment, welder, trailer, tractor, etc. The rest of ya'll norte tejas TBN'rs kick in helping hands and we'll have a bridge building one saturday or sunday.

Alan can spring for four pieces of two by four eleven gauge twenty four foot long along with whatever he wants for decking, wood, expanded metal etc. That and some posts for the ends along with whatever concrete he needs we can do it in a day. Or at least have it where he can deck it by himself if necessary.

The plan. I'll lay out a pattern on on piece of the rectangular tubing. A couple of guys can do what that requires. When they're done I'll weld that piece up and we can have someone else grind the welds. When we're done we'll have three arc'd pieces with about a three foot rise in the middle. The fourth piece of tubing will be for connectors between the three.

We'll need an M.E. to verify the load capacity for a bridge so designed. I only think'em up and make'm. Someone else has to tell me I did right or wrong.

We would have to have Bird there. A TBN affair in norte tejas without Bird would be almost like one of those they have in New England. /forums/images/graemlins/grin.gif

Seriously, it could be fun. This time of year we'd all already be wearing boots so the tractor tales could, well, we'd have more'n one. /forums/images/graemlins/grin.gif

Besides that, we could set the standard for TBN get togethers. Do a project, best mixer ever.

You're right. And heck, I've known John at least ten plus years. /forums/images/graemlins/blush.gif /forums/images/graemlins/blush.gif /forums/images/graemlins/blush.gif Old age getting me again. /forums/images/graemlins/blush.gif

If I recall this bridge is only needed for a thousand pounds or so. It looks like a twenty footer will do just fine.

Here's a suggestion. I'll supply the equipment, welder, trailer, tractor, etc. The rest of ya'll norte tejas TBN'rs kick in helping hands and we'll have a bridge building one saturday or sunday.

Alan can spring for four pieces of two by four eleven gauge twenty four foot long along with whatever he wants for decking, wood, expanded metal etc. That and some posts for the ends along with whatever concrete he needs we can do it in a day. Or at least have it where he can deck it by himself if necessary.

The plan. I'll lay out a pattern on on piece of the rectangular tubing. A couple of guys can do what that requires. When they're done I'll weld that piece up and we can have someone else grind the welds. When we're done we'll have three arc'd pieces with about a three foot rise in the middle. The fourth piece of tubing will be for connectors between the three.

We'll need an M.E. to verify the load capacity for a bridge so designed. I only think'em up and make'm. Someone else has to tell me I did right or wrong.

We would have to have Bird there. A TBN affair in norte tejas without Bird would be almost like one of those they have in New England. /forums/images/graemlins/grin.gif

Seriously, it could be fun. This time of year we'd all already be wearing boots so the tractor tales could, well, we'd have more'n one. /forums/images/graemlins/grin.gif

Besides that, we could set the standard for TBN get togethers. Do a project, best mixer ever.

BillG_in_TX

Veteran Member

wroughtn_harv

Super Member

</font><font color="blue" class="small">( I'll bring a good attitude!)</font>

I knew that!

You're a TBN'r.

A bud makes some of the best trailers, carhaulers, in the world using two by four eleven gauge. When you add in the strength of the arc I'll bet this framework can hold more than a Texan on a Mule.

The way I arc rectangular tubing is I lay out and cut slits with a portable bandsaw. I have my cuts on the outside of the arc. I generally go for a spread of each cut that's about twice the size of the cut itself. For a tight radius I put the cuts close together and for a slower one, farther apart. I then weld up the gaps and then grind them smooth. Folks who see some of my work just assume I have a roller with some kind of capacity. In fact it's just a little work and a lot of patience.

More important than the arc will be the footers--posts at the edges of the bridge. They have to be substantial enough to resist the tendancy of the arc to straighten out when there's a load. We could put some horizontal braces to make it really strong but that would take away from the beauty of the arc and provide a place for debris to hang up when the water's flowing high.

I knew that!

You're a TBN'r.

A bud makes some of the best trailers, carhaulers, in the world using two by four eleven gauge. When you add in the strength of the arc I'll bet this framework can hold more than a Texan on a Mule.

The way I arc rectangular tubing is I lay out and cut slits with a portable bandsaw. I have my cuts on the outside of the arc. I generally go for a spread of each cut that's about twice the size of the cut itself. For a tight radius I put the cuts close together and for a slower one, farther apart. I then weld up the gaps and then grind them smooth. Folks who see some of my work just assume I have a roller with some kind of capacity. In fact it's just a little work and a lot of patience.

More important than the arc will be the footers--posts at the edges of the bridge. They have to be substantial enough to resist the tendancy of the arc to straighten out when there's a load. We could put some horizontal braces to make it really strong but that would take away from the beauty of the arc and provide a place for debris to hang up when the water's flowing high.

BB_TX

Veteran Member

- Joined

- Jan 29, 2002

- Messages

- 1,939

- Tractor

- JD 950

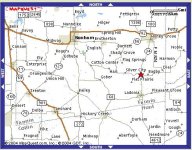

<font color="blue"> I found it - see attached map. It's between Ladonia and Honey Grove. </font>

Alan is going to have to straighten us out. I found Bugtussle in Fannin county and Mustang in Denton county. But Alan also says he is in Grayson county. Wow, he must have a big place. /forums/images/graemlins/shocked.gif

Alan is going to have to straighten us out. I found Bugtussle in Fannin county and Mustang in Denton county. But Alan also says he is in Grayson county. Wow, he must have a big place. /forums/images/graemlins/shocked.gif

Bird

Rest in Peace

</font><font color="blue" class="small">( We would have to have Bird there. )</font>

Sounds like fun to me; just let me know when and where.

Sounds like fun to me; just let me know when and where.

wroughtn_harv

Super Member

</font><font color="blue" class="small">( Sounds like fun to me; just let me know when and where. )</font>

Doesn't it though?

If we can talk Alan to name his creek "troubled waters" maybe we can find someone famous to write a theme song just for our event. /forums/images/graemlins/crazy.gif

Doesn't it though?

If we can talk Alan to name his creek "troubled waters" maybe we can find someone famous to write a theme song just for our event. /forums/images/graemlins/crazy.gif

Hay, I missed a day on TNB, but this is starting to really sound good!! Actually Bugtussle refers to the old school on 902 between Dorchester and Collinsville. Mustang is an unincorporated town between Celina and Pilot Point.

Actually I'm several miles north of Mustang and several miles south of the old Bugtussle school, off of FM 121 between Gunter and Tioga (theres an "Gunter" somewhere around Greenville, but the "real" Gunter is in Grayson county).

Buck creek runs through my property and then into Lake Ray Roberts.

This sounds like a lot of fun, more for me than any of you since I would be on the receiving end of the deal. I can dang sure handle the materials and supplies. The only problem with timing would be the weather conditions, since the area can get soggy in wet weather, and of course the creek can get up in heavy rains. However, it seems like having water in the creek would not be of too much consequence since the footings would be back away from the water, as long as its not high enough that I can't get the mule/tractor or whatever, over the low water crossing upstream.

Sounds like some planning would be in order. I wonder if it would be a good idea to have the footings already done ahead of time, since the concrete would have to cure?

It would probably take several bucket loads with my little tractor to haul off all the BS at the end of the day.....

Actually I'm several miles north of Mustang and several miles south of the old Bugtussle school, off of FM 121 between Gunter and Tioga (theres an "Gunter" somewhere around Greenville, but the "real" Gunter is in Grayson county).

Buck creek runs through my property and then into Lake Ray Roberts.

This sounds like a lot of fun, more for me than any of you since I would be on the receiving end of the deal. I can dang sure handle the materials and supplies. The only problem with timing would be the weather conditions, since the area can get soggy in wet weather, and of course the creek can get up in heavy rains. However, it seems like having water in the creek would not be of too much consequence since the footings would be back away from the water, as long as its not high enough that I can't get the mule/tractor or whatever, over the low water crossing upstream.

Sounds like some planning would be in order. I wonder if it would be a good idea to have the footings already done ahead of time, since the concrete would have to cure?

It would probably take several bucket loads with my little tractor to haul off all the BS at the end of the day.....

wroughtn_harv

Super Member

The weather could be a problem. Lucy will get stuck just cause she can. And good lawd, she can. /forums/images/graemlins/confused.gif

So we need to have it dry enough for her to get within a couple of hundred feet of the project. I've got leads and power cords to cover that.

We'll have to get together to decide what you want in the design. We want it to be nice enough to be able to have a TBN Project plate.

I don't know about the rest of the guys but I would like to see it happen on a weekend. Mostly because my wife is always complaining about me having all the fun. I get to meet some of the nicest people and do the most fun things. She sits at a CRT with a headset and attempting to help people with their telephone service. She loves being outside and she's a great worker too.

She's a member in her own way. Every morning as I cruise TBN she's reading over my shoulder as she irons her clothes for the day. She knows most of you as well if not better than I do. Besides that, Even Muhammad, Ibrahim, and Hakim will tell you she's the best thing about me.

This could be some real fun.

So we need to have it dry enough for her to get within a couple of hundred feet of the project. I've got leads and power cords to cover that.

We'll have to get together to decide what you want in the design. We want it to be nice enough to be able to have a TBN Project plate.

I don't know about the rest of the guys but I would like to see it happen on a weekend. Mostly because my wife is always complaining about me having all the fun. I get to meet some of the nicest people and do the most fun things. She sits at a CRT with a headset and attempting to help people with their telephone service. She loves being outside and she's a great worker too.

She's a member in her own way. Every morning as I cruise TBN she's reading over my shoulder as she irons her clothes for the day. She knows most of you as well if not better than I do. Besides that, Even Muhammad, Ibrahim, and Hakim will tell you she's the best thing about me.

This could be some real fun.

I stayed up half the night trying to engineer this thing. What I can see drilling 2 9" post holes on either side of the creek. Have to try to get them square with one another, which is a problem because the creek is pretty much impassible when it has water in it, and fairly difficult to cross right here even when its dry, due to steep creek banks.

The posts (some sort of metal posts I guess - something like water well casing depending on cost) would be cemented. Then about a foot-deep hole would be excavated between each pair of posts and some reoar put in there. Then, build forms to build up the footings another foot or so, so that the concrete is 2 feet thick.

Depending on design, if the beams need to be anchored to the footings themselves, then threaded studs will need to be set in the top of the footings in the exact locations needed, to bolt the beams down to.

As an alternative, using an all metal frame design, all of the frame could be welded between each pair of metal poles, and the rest of the concrete footing might not even be necessary at all. My PHD will dig about 36" deep, hopefully that would be deep enough to anchor the posts. Perhaps a 12" auger is needed.

The Kawasaki mule that I currently own weighs about 1200 pounds, so with two people in it, and some cargo, figure 2000 pounds. The bridge will primarily be for foot traffic however.

The arched design Wroughtn_Harv is describing sounds very good to me, although its sounds like a lot of sawing and welding on his part. The bridge will need some handrails also (so my grandchildren don't fall in the creek), which would seem difficult in an arched design since everything has to be curved.

I would be perfectly happy with a straight, not arched bridge as my second choice. If its 6 feet wide, it would seem to need four beams, so the decking would only span 24" between beams.

When the bridge is done, later on I plan to run a water line across the creek, and figured the structure of the bridge would be the logical place to run it, although I would need some way to keep the pipes from freezing.

Am I correct in assuming the cement anchoring the posts would need to be set up before any major work is done on the span? Assuming this, it would seem that this would need to be done ahead of time. This might only consist of setting 4 posts, no other concrete footings at all. Also, I suppose the posts could be left sticking up at lease as high as the handrails would be, then cut off later to the proper height.

Of course about July is the driest time to be working on the creek, but it is also pretty dang HOT about then.....

This is the stuff that kept me up all night......

The posts (some sort of metal posts I guess - something like water well casing depending on cost) would be cemented. Then about a foot-deep hole would be excavated between each pair of posts and some reoar put in there. Then, build forms to build up the footings another foot or so, so that the concrete is 2 feet thick.

Depending on design, if the beams need to be anchored to the footings themselves, then threaded studs will need to be set in the top of the footings in the exact locations needed, to bolt the beams down to.

As an alternative, using an all metal frame design, all of the frame could be welded between each pair of metal poles, and the rest of the concrete footing might not even be necessary at all. My PHD will dig about 36" deep, hopefully that would be deep enough to anchor the posts. Perhaps a 12" auger is needed.

The Kawasaki mule that I currently own weighs about 1200 pounds, so with two people in it, and some cargo, figure 2000 pounds. The bridge will primarily be for foot traffic however.

The arched design Wroughtn_Harv is describing sounds very good to me, although its sounds like a lot of sawing and welding on his part. The bridge will need some handrails also (so my grandchildren don't fall in the creek), which would seem difficult in an arched design since everything has to be curved.

I would be perfectly happy with a straight, not arched bridge as my second choice. If its 6 feet wide, it would seem to need four beams, so the decking would only span 24" between beams.

When the bridge is done, later on I plan to run a water line across the creek, and figured the structure of the bridge would be the logical place to run it, although I would need some way to keep the pipes from freezing.

Am I correct in assuming the cement anchoring the posts would need to be set up before any major work is done on the span? Assuming this, it would seem that this would need to be done ahead of time. This might only consist of setting 4 posts, no other concrete footings at all. Also, I suppose the posts could be left sticking up at lease as high as the handrails would be, then cut off later to the proper height.

Of course about July is the driest time to be working on the creek, but it is also pretty dang HOT about then.....

This is the stuff that kept me up all night......

Bird

Rest in Peace

</font><font color="blue" class="small">( I don't know about the rest of the guys but I would like to see it happen on a weekend )</font>

For us old retired folks, it doesn't matter, but I'd think it would almost have to be a weekend 'cause a lot of the others still have jobs they have to go to during the week.

For us old retired folks, it doesn't matter, but I'd think it would almost have to be a weekend 'cause a lot of the others still have jobs they have to go to during the week.

wroughtn_harv

Super Member

Morning Alan,

Squaring up the posts isn't a big thing.

Iris can drill a two foot hole eight feet deep. I also have twelve and sixteen inch augers. The holes are nothing but a thing.

I was wondering about the hand rails. In fact I'd already figured out a system for them that's easy.

I think the three beam thing will work just fine. One in the middle and another on each side that would be under the track of the Mule. An six foot wide bridge would have beams at twelve inches in, another at thirty six and the last at sixty. The handrail isn't that much harder on an arc than it is on a straight line. And it's a whole lot more fun to do.

For the hand rail we could use either small pipe (inch and a quarter or inch and a half) or square tubing. We'd need fourteen of these pieces. They'd be shaped like an "L" with the horizontal leg going back to the beam. These would be welded into place. The vertical leg would be the supports for the hand rail. The handrail could be wood attached to the steel via self tapping screws. They could be steel with wood or just steel.

As for your plumbing. I'd suggest hanging a piece of four inch PVC under the bridge. Your water line could be ran through this. The insulation foam that comes in cans could be injected and your water line would be insulated besides being protected.

If we use a product like Maximizer to set the posts we can set them and weld up the framework in one day. Then you can form up your approaches, lay down your decking, and paint at your own pace. Providing you supply pictures of course. /forums/images/graemlins/grin.gif

If you don't mind the maintenance the bridge could be finished out in cedar. It would be spectacular and the steel framework would disappear.

Adding rock to the approaches would take it to whole nother level. Bringing in low voltage lighting could make it a focal point.

Those are all options that you can or not do based upon what you and your family want.

I don't know if you have a screw gun yet. Or even a decent mitre saw. But if you're so inclined this project finished out in wood could justify those purchases. I'm not one to corrupt one but I can be manipulated.

Squaring up the posts isn't a big thing.

Iris can drill a two foot hole eight feet deep. I also have twelve and sixteen inch augers. The holes are nothing but a thing.

I was wondering about the hand rails. In fact I'd already figured out a system for them that's easy.

I think the three beam thing will work just fine. One in the middle and another on each side that would be under the track of the Mule. An six foot wide bridge would have beams at twelve inches in, another at thirty six and the last at sixty. The handrail isn't that much harder on an arc than it is on a straight line. And it's a whole lot more fun to do.

For the hand rail we could use either small pipe (inch and a quarter or inch and a half) or square tubing. We'd need fourteen of these pieces. They'd be shaped like an "L" with the horizontal leg going back to the beam. These would be welded into place. The vertical leg would be the supports for the hand rail. The handrail could be wood attached to the steel via self tapping screws. They could be steel with wood or just steel.

As for your plumbing. I'd suggest hanging a piece of four inch PVC under the bridge. Your water line could be ran through this. The insulation foam that comes in cans could be injected and your water line would be insulated besides being protected.

If we use a product like Maximizer to set the posts we can set them and weld up the framework in one day. Then you can form up your approaches, lay down your decking, and paint at your own pace. Providing you supply pictures of course. /forums/images/graemlins/grin.gif

If you don't mind the maintenance the bridge could be finished out in cedar. It would be spectacular and the steel framework would disappear.

Adding rock to the approaches would take it to whole nother level. Bringing in low voltage lighting could make it a focal point.

Those are all options that you can or not do based upon what you and your family want.

I don't know if you have a screw gun yet. Or even a decent mitre saw. But if you're so inclined this project finished out in wood could justify those purchases. I'm not one to corrupt one but I can be manipulated.