Ken45101

Elite Member

- Joined

- Feb 14, 2009

- Messages

- 3,679

- Location

- southern Ohio

- Tractor

- Kubota M5040, M9540, B21 TLB, B2710, RTV900, JD 325 Skid steer, KX-121-3 mini excavator

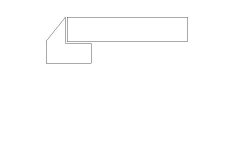

My Kubota L3010 with cutter and fully loaded front loader should never exceed this lb limit.

What happens when you decide to upgrade to a bigger tractor five or ten years from now?

Personally, I would not design for "should never exceed". I would go with a minimum of 2x or 3x capacity.

Also, are you considering the weight of the decking material?

Does the creek flood? A couple of miles down the road, a guy put in some nice piers and set a flat bed truck trailer on it for a bridge. He built up some nice approaches with creek rock. The first good gully washer washed out the approaches and moved the deck a couple of feet