Hello,

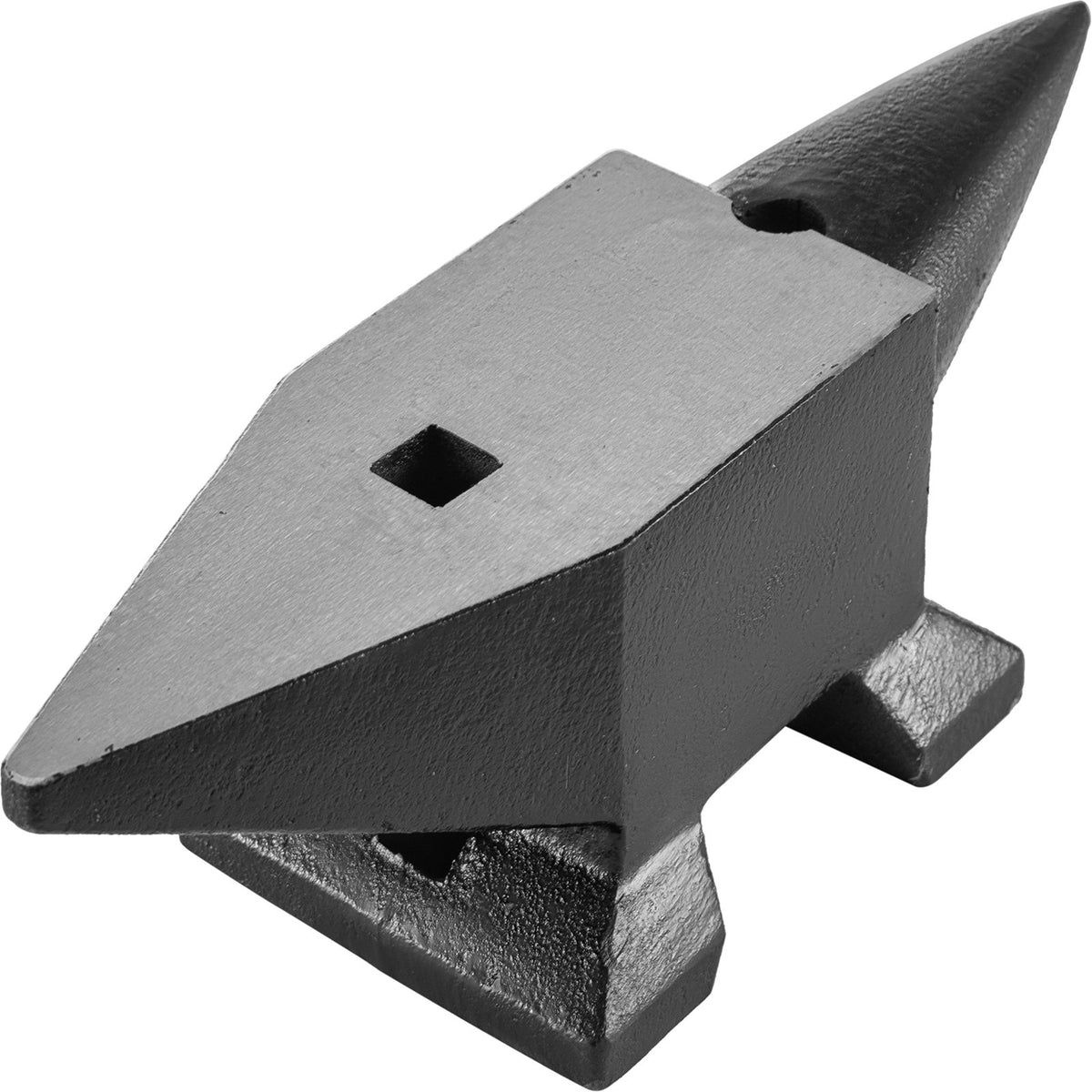

I was attempting to hardface a make-shift anvil for use at home, because real anvils are so dang expensive. Was putting on the hardfacing rod after pre-heating the block, and I saw what you see in the picture. I was even peening the beads, but it still cracked all over the place. What do I do now?? Am I just SOL?

Thanks

I was attempting to hardface a make-shift anvil for use at home, because real anvils are so dang expensive. Was putting on the hardfacing rod after pre-heating the block, and I saw what you see in the picture. I was even peening the beads, but it still cracked all over the place. What do I do now?? Am I just SOL?

Thanks