my b7800 makes a GRRRRRRR noise coming from drive shaft dealer took it apart about 5yrs back said was full of weeds . must not have been a big job. I live 1hr away from dealer and called when I got home said was fixed .told me the cover over the shaft was stuffed with weeds. its doing it again. I,m handy and do it myself with a little guidance. any help appr.jim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B7800 4x4 2007 how to remove front drive shaft

- Thread starter ohiojim

- Start date

- Views: 10213

-

- Tags

- kubota b7800

/ B7800 4x4 2007 how to remove front drive shaft

#1

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 32,246

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Not a lot of 7800s on here. Even less with owners that would do this project.

I can't imagine it's that hard to remove the cover. Crawl under there and take a look. Post pics if you get stumped and can't figure it out.

I can't imagine it's that hard to remove the cover. Crawl under there and take a look. Post pics if you get stumped and can't figure it out.

riptides

Super Member

I have a 2003 B (FIRST model year), never heard of this issue before. I'll have to take a look at mine and see what is going on down there.

orezok

Elite Member

Rockwood Equipment

New member

- Joined

- Dec 13, 2020

- Messages

- 5

- Tractor

- Kubota B7900

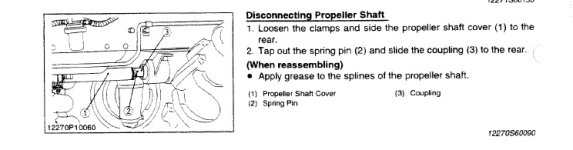

I just finished replacing a drive front drive shaft on a B7800. The dealer says you have to pull the tranny and the loader frame (at least 12 hrs labor) to access the u-joints in the drive shaft.

I took off the fender deck rubber hoping for an access panel but there wasn't one. At that point I was resigned to splitting the tractor until I remembered a 2 1/8" carbide holesaw I had which cut a beautiful access hole.

When you cut it, beware of the hydraulic line that's dead center on the point of the trans, so stay to the right and you'll be good.

These U-Joints use double roll pins, drive the inner pin out and then the outer. Slide the U joint off. I made a driver out of a pneumatic hand nailer. I originally built it for body panels but by grinding a pin from a harbor freight punch I can install and remove pins in tough access areas like underneath the tractor with a loose shaft that has a roll pin in the u-joint. To remove the large roll pin I install the pin in the hole in the hammer head, to install I removed the driver pin and the roll pins fit into the hole perfectly.

Remove the entire front axle and drain it.

Remove the two 12mm center support bolts and other clamps to remove the lower shaft and snake it out the front.

Pull out the upper shaft and remove the U-Joint . I found my u-joints were still tight but their splines were worn, the upper shaft had at least an 1/8" of slop and the center U Joint ate the plastic cover. Now it's tight, no slop.

Use plenty of grease or never seize on the splines.

One thing that will save you massive frustration is that the sliding side of the center U-Joint is INDEXED!!!!!! Even though there is no indication on the shaft there is in the female spline It will only fit one way.

Put the new upper U-joint on and slide it up into place. Connect the sliding joint and get the support ready to go back.

Move the whole thing back and connect the trans.

Install the two carrier bolts and put the rest back together.

The workshop manual for this project is absolutely worthless so don't waste your money!

I took off the fender deck rubber hoping for an access panel but there wasn't one. At that point I was resigned to splitting the tractor until I remembered a 2 1/8" carbide holesaw I had which cut a beautiful access hole.

When you cut it, beware of the hydraulic line that's dead center on the point of the trans, so stay to the right and you'll be good.

These U-Joints use double roll pins, drive the inner pin out and then the outer. Slide the U joint off. I made a driver out of a pneumatic hand nailer. I originally built it for body panels but by grinding a pin from a harbor freight punch I can install and remove pins in tough access areas like underneath the tractor with a loose shaft that has a roll pin in the u-joint. To remove the large roll pin I install the pin in the hole in the hammer head, to install I removed the driver pin and the roll pins fit into the hole perfectly.

Remove the entire front axle and drain it.

Remove the two 12mm center support bolts and other clamps to remove the lower shaft and snake it out the front.

Pull out the upper shaft and remove the U-Joint . I found my u-joints were still tight but their splines were worn, the upper shaft had at least an 1/8" of slop and the center U Joint ate the plastic cover. Now it's tight, no slop.

Use plenty of grease or never seize on the splines.

One thing that will save you massive frustration is that the sliding side of the center U-Joint is INDEXED!!!!!! Even though there is no indication on the shaft there is in the female spline It will only fit one way.

Put the new upper U-joint on and slide it up into place. Connect the sliding joint and get the support ready to go back.

Move the whole thing back and connect the trans.

Install the two carrier bolts and put the rest back together.

The workshop manual for this project is absolutely worthless so don't waste your money!

Last edited:

Henro

Elite Member

- Joined

- Jul 4, 2003

- Messages

- 4,978

- Location

- Few miles north of Pgh, PA

- Tractor

- Kubota B2910, BX2200, KX41-2V mini EX

Good info.

Did you take any pictures you could post?

If possible, perhaps you could edit your post into smaller paragraphs for easier reading.

Thanks for posting that information. Certainly helpful for those of us with B2710/B2910/B7800 tractors.

Actually I did that for my own benefit. Will post it here and save you the trouble...

B7800 front U-Joint Replacement

I just finished replacing a drive front drive shaft on a B7800. The dealer says you have to pull the tranny and the loader frame (at least 12 hrs labor) to access the u-joints in the drive shaft.

I took off the fender deck rubber hoping for an access panel but there wasn't one. At that point I was resigned to splitting the tractor until I remembered a 2 1/8" carbide holesaw I had which cut a beautiful access hole.

When you cut it, beware of the hydraulic line that's dead center on the point of the trans, so stay to the right and you'll be good.

These U-Joints use double roll pins, drive the inner pin out and then the outer. Slide the U joint off.

Remove the entire front axle and drain it.

Remove the two 12mm center support bolts and other clamps to remove the lower shaft and snake it out the front.

Pull out the upper shaft and remove the U-Joint . I found my u-joints were still tight but their splines were worn, the upper shaft had at least an 1/8" of slop and the center U Joint ate the plastic cover. Now it's tight, no slop.

Use plenty of grease or never seize on the splines.

One thing that will save you massive frustration is that the sliding side of the center U-Joint is INDEXED!!!!!! Even though there is no indication on the shaft there is in the female spline It will only fit one way.

Put the new upper U-joint on and slide it up into place. Connect the sliding joint and get the support ready to go back.

Move the whole thing back and connect the trans.

Install the two carrier bolts and put the rest back together.

Did you take any pictures you could post?

If possible, perhaps you could edit your post into smaller paragraphs for easier reading.

Thanks for posting that information. Certainly helpful for those of us with B2710/B2910/B7800 tractors.

Actually I did that for my own benefit. Will post it here and save you the trouble...

B7800 front U-Joint Replacement

I just finished replacing a drive front drive shaft on a B7800. The dealer says you have to pull the tranny and the loader frame (at least 12 hrs labor) to access the u-joints in the drive shaft.

I took off the fender deck rubber hoping for an access panel but there wasn't one. At that point I was resigned to splitting the tractor until I remembered a 2 1/8" carbide holesaw I had which cut a beautiful access hole.

When you cut it, beware of the hydraulic line that's dead center on the point of the trans, so stay to the right and you'll be good.

These U-Joints use double roll pins, drive the inner pin out and then the outer. Slide the U joint off.

Remove the entire front axle and drain it.

Remove the two 12mm center support bolts and other clamps to remove the lower shaft and snake it out the front.

Pull out the upper shaft and remove the U-Joint . I found my u-joints were still tight but their splines were worn, the upper shaft had at least an 1/8" of slop and the center U Joint ate the plastic cover. Now it's tight, no slop.

Use plenty of grease or never seize on the splines.

One thing that will save you massive frustration is that the sliding side of the center U-Joint is INDEXED!!!!!! Even though there is no indication on the shaft there is in the female spline It will only fit one way.

Put the new upper U-joint on and slide it up into place. Connect the sliding joint and get the support ready to go back.

Move the whole thing back and connect the trans.

Install the two carrier bolts and put the rest back together.

Rockwood Equipment

New member

- Joined

- Dec 13, 2020

- Messages

- 5

- Tractor

- Kubota B7900

Thanks for the edit. I'll try and post some pics. It says they'll accept PNG files (it's a genius apple thing). Anyway I have some pics.

Rockwood Equipment

New member

- Joined

- Dec 13, 2020

- Messages

- 5

- Tractor

- Kubota B7900

Rockwood Equipment

New member

- Joined

- Dec 13, 2020

- Messages

- 5

- Tractor

- Kubota B7900

Henro

Elite Member

- Joined

- Jul 4, 2003

- Messages

- 4,978

- Location

- Few miles north of Pgh, PA

- Tractor

- Kubota B2910, BX2200, KX41-2V mini EX

I see you figured out the picture thing. :thumbsup:

The pictures showing the position of the hole you cut will be very useful to someone trying to do the same thing in the future.

What is going on in the last picture with the vise?

The pictures showing the position of the hole you cut will be very useful to someone trying to do the same thing in the future.

What is going on in the last picture with the vise?