LD1

Epic Contributor

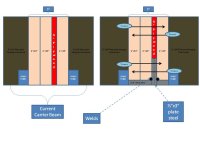

The pictures and diagrams paint a whole different picture.

If I understand them correctly, you are building a wall under one side of the beam that will continue half of the distance. And instead of haveing the beam divided into 3 spaces, you are wanting to have the 17' side clear-span.

If that is the case, You shouldn't need to worry about the side with the wall being built under it. EACH of the studs is going to act like a post and carry the load int the floor. So I wouldn't touch that side.

Now that we are only dealing with the 17foot section, As I currently understand it, it is all open underneath with the exception of the 1 post about 4'6" from the wall you are building and a 12'6" space on the other side all the way to the foundation wall correct?? Your goal is to eliminate that "off center" post and clear span it right???

You have a few options here. 1st woudl be to not touch the beam and just add a post @ the mid point of that 17' span. While not clearspanning, it would certainly look better than the current off-center post.

I don't currently have the load abilities of LVL's in front of be but I would think that a double 14" or 16" would certainly do it. But LVL's are pricey and you will give up head room. If you can afford the headroom, that sounds like the way to go. If the headroom is an issue, steel is about the only option you have left. You can get a beam pleanty strong enough and still not go over the 10" deapth you currently have.

If I understand them correctly, you are building a wall under one side of the beam that will continue half of the distance. And instead of haveing the beam divided into 3 spaces, you are wanting to have the 17' side clear-span.

If that is the case, You shouldn't need to worry about the side with the wall being built under it. EACH of the studs is going to act like a post and carry the load int the floor. So I wouldn't touch that side.

Now that we are only dealing with the 17foot section, As I currently understand it, it is all open underneath with the exception of the 1 post about 4'6" from the wall you are building and a 12'6" space on the other side all the way to the foundation wall correct?? Your goal is to eliminate that "off center" post and clear span it right???

You have a few options here. 1st woudl be to not touch the beam and just add a post @ the mid point of that 17' span. While not clearspanning, it would certainly look better than the current off-center post.

I don't currently have the load abilities of LVL's in front of be but I would think that a double 14" or 16" would certainly do it. But LVL's are pricey and you will give up head room. If you can afford the headroom, that sounds like the way to go. If the headroom is an issue, steel is about the only option you have left. You can get a beam pleanty strong enough and still not go over the 10" deapth you currently have.