dieselscout80

Veteran Member

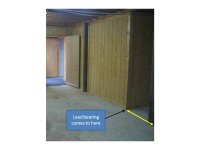

I want to know how far a beam can span. I finishing my basement.

Beam in questions is made of three 2"x10" and a 1/2' sheet of plywood nailed together.

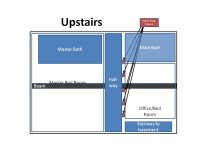

It is part of the main floor of my house and has floor 2"x10" joists attached perpendicular on both sides on 16" centers. The joists are supported by the block foundation on both sides one side spans about 11'9" the 12'3". The load above the beam is a hallway and a bed room/office and in the attic there are 5 roof truss supports.

I want to span 17' if possible without additional supports.

First question can the existing beam support the 17' foot span?

Second what do I need to do to reinforce the existing beam?

I've thought about running another beam under it made from 20' either 2"x6", 2"x8" or 2"x10" with 1/2" plywood and attach it to the existing beam with metal plates between the joists.

I've thought about running another beam under it made from 20' either 2"x4", 2"x6" steel and attach it to the existing beams.

A friend who is a ENG mentioned cutting the plywood out and taking a I beam with a 7" web and having the the top flange removed and placing it where the plywood was and then bolting through the 2"x10". How would I cut the plywood out my only idea has been a chainsaw?

Could I use 3 x 2 x 3/16 Steel Angle on both sides of the existing beam and bolt it through and do the same thing?

Beam in questions is made of three 2"x10" and a 1/2' sheet of plywood nailed together.

It is part of the main floor of my house and has floor 2"x10" joists attached perpendicular on both sides on 16" centers. The joists are supported by the block foundation on both sides one side spans about 11'9" the 12'3". The load above the beam is a hallway and a bed room/office and in the attic there are 5 roof truss supports.

I want to span 17' if possible without additional supports.

First question can the existing beam support the 17' foot span?

Second what do I need to do to reinforce the existing beam?

I've thought about running another beam under it made from 20' either 2"x6", 2"x8" or 2"x10" with 1/2" plywood and attach it to the existing beam with metal plates between the joists.

I've thought about running another beam under it made from 20' either 2"x4", 2"x6" steel and attach it to the existing beams.

A friend who is a ENG mentioned cutting the plywood out and taking a I beam with a 7" web and having the the top flange removed and placing it where the plywood was and then bolting through the 2"x10". How would I cut the plywood out my only idea has been a chainsaw?

Could I use 3 x 2 x 3/16 Steel Angle on both sides of the existing beam and bolt it through and do the same thing?