3Lfarms

Platinum Member

I have a problem I have thus far been unable to figure out and I’m wondering if one of you can give me an idea how I can remove this bearing without causing any damage to either the bearing or shaft.

I can’t tell you what it’s for, but it is an aircraft part. Problem is, I can’t get a new bearing, but I need the bearing removed to mag particle inspect the shaft. We need to be able to inspect and reuse the bearing. The lead time to get a new certified bearing is almost a year.

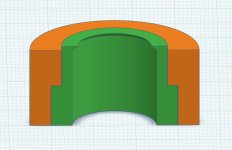

The space between the bearing and splined area is so small a standard bearing separator can’t fit between the bearing and splines.

I broke one bearing trying to hold it in a vice so I could press out the shaft.

The bearing is a press fit on the shaft and it took a about half a ton of pressure to get the inner race of the broken bearing off the shaft.

Is there a special tool that could help me?

I can’t tell you what it’s for, but it is an aircraft part. Problem is, I can’t get a new bearing, but I need the bearing removed to mag particle inspect the shaft. We need to be able to inspect and reuse the bearing. The lead time to get a new certified bearing is almost a year.

The space between the bearing and splined area is so small a standard bearing separator can’t fit between the bearing and splines.

I broke one bearing trying to hold it in a vice so I could press out the shaft.

The bearing is a press fit on the shaft and it took a about half a ton of pressure to get the inner race of the broken bearing off the shaft.

Is there a special tool that could help me?