Buty

Silver Member

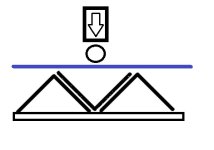

I am making a back shield for a tiller and have a piece of 14" x 60" piece of 10 gauge hot roll material that I need to put a bend in lengthwise. Any thoughts on how to do this without a brake?

Should I just weld some flat bar to the edge to make it stronger?

Should I just weld some flat bar to the edge to make it stronger?