LindenBruce

Gold Member

Hello All,

Well, I was out working some dirt. I had just finished digging a hole and was ready to move on. Lifted the FEL. Then went to curl the FEL bucket back and nothing happened. Suddenly a curtain of oil rained down from behind the bucket. I broken hydraulic line. How frustrating. I've had this unit for like 14 months and just hit the century mark on the hour meter and another failure.

Drove around to the barn and pulled the cover off. And sure enough the steel line had burst. SMH. Sent an email to my dealer but being after hours I won't hear anything until tomorrow. Knowing my luck it will be a week before I see the part. And I have a lot of work to get done before the rains hit. Which could be anytime now.

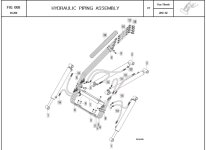

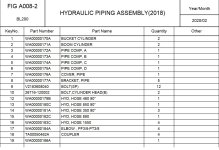

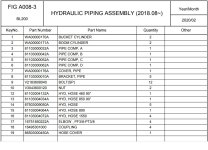

I found two part numbers for the tube online in a PDF for the loader. One part is #WA00000172A and the other is #81103000032A. I searched for those and they only point back to the darn PDF of the loader break down. What use is a listed part number if it only points back to the source. And not to a business selling that item? Totally useless. Well, I guess I wait and see tomorrow. Frustrating. B.

Well, I was out working some dirt. I had just finished digging a hole and was ready to move on. Lifted the FEL. Then went to curl the FEL bucket back and nothing happened. Suddenly a curtain of oil rained down from behind the bucket. I broken hydraulic line. How frustrating. I've had this unit for like 14 months and just hit the century mark on the hour meter and another failure.

Drove around to the barn and pulled the cover off. And sure enough the steel line had burst. SMH. Sent an email to my dealer but being after hours I won't hear anything until tomorrow. Knowing my luck it will be a week before I see the part. And I have a lot of work to get done before the rains hit. Which could be anytime now.

I found two part numbers for the tube online in a PDF for the loader. One part is #WA00000172A and the other is #81103000032A. I searched for those and they only point back to the darn PDF of the loader break down. What use is a listed part number if it only points back to the source. And not to a business selling that item? Totally useless. Well, I guess I wait and see tomorrow. Frustrating. B.