Slowpoke Slim

Elite Member

- Joined

- Jan 6, 2017

- Messages

- 3,916

- Location

- Bismarck, ND

- Tractor

- Husqvarna YTH24V48 riding mower, Branson 3725CH

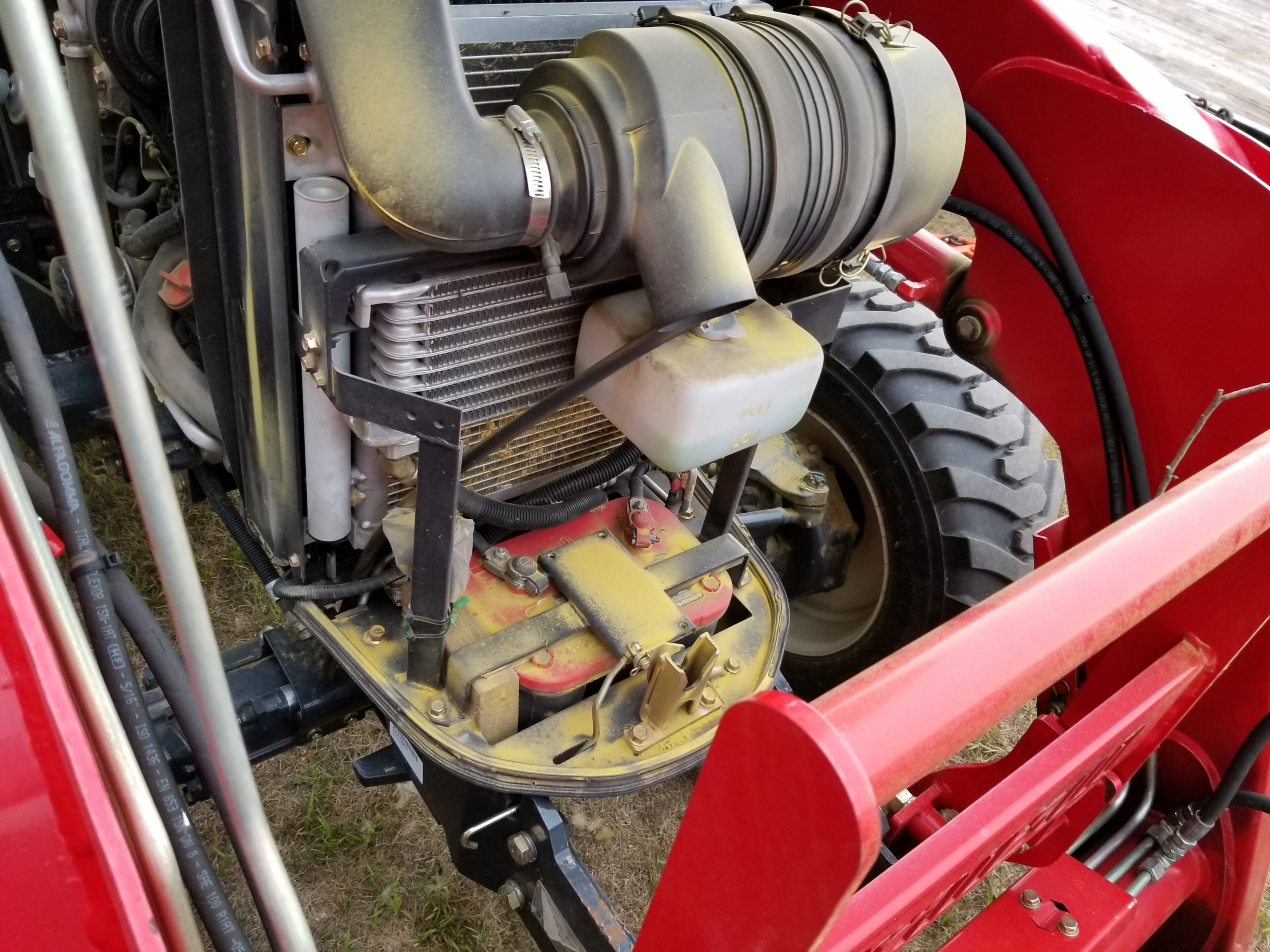

Just want to throw out there that after mowing and using my cabbed tractor with A/C, you really have to blow out your radiator and coolers every time you mow.

And if you're mowing all day, or several days in a row, you should plan on stopping a couple of times a day and blow everything out. Any new tractor I look at has a "modern" radiator and coolers, which means the rows and fins are *much* tighter spacing than tractors of yesteryear. They will absolutely fill in with chaff as you mow.

This was after only a couple of hours of mowing (and it started off clean).

When I mowed at home, I would pull up to the shop and use my big shop compressor and a handy air wand. When I'm mowing out at a remote site, I take along a pancake compressor and generator. The little pancake takes longer, as it can't keep up with the air demand from the wand, but it has to be done. Else wise you have overheating issues that can pop a radiator and cause your A/C to blow warm/hot due to poor heat exchange.

And if you're mowing all day, or several days in a row, you should plan on stopping a couple of times a day and blow everything out. Any new tractor I look at has a "modern" radiator and coolers, which means the rows and fins are *much* tighter spacing than tractors of yesteryear. They will absolutely fill in with chaff as you mow.

This was after only a couple of hours of mowing (and it started off clean).

When I mowed at home, I would pull up to the shop and use my big shop compressor and a handy air wand. When I'm mowing out at a remote site, I take along a pancake compressor and generator. The little pancake takes longer, as it can't keep up with the air demand from the wand, but it has to be done. Else wise you have overheating issues that can pop a radiator and cause your A/C to blow warm/hot due to poor heat exchange.