LD1

Epic Contributor

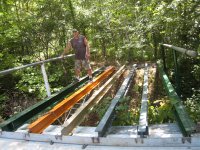

Didn't see any pictures of the splice, which is perhaps the most critical part of what you are doing.

You said you plated the sides (web), but in reality.....you really should splice the flanges.....at least the bottom.

You said you plated the sides (web), but in reality.....you really should splice the flanges.....at least the bottom.