NoTrespassing

Elite Member

The last time I removed my loader I screwed up, it had been awhile and I was doing things out of order. I know you say you've done it a few hundred times and I'm not saying you're doing anything wrong but it can happen.I can connect all 4 hoses.

good advice on taking the loader in with the tractor. It all fits on my trailer.

in the photo, the lever is in the detent position, and is unlocked. The lever releases from the detent position as usual and moves as it should, although pushing it forward, it feels a little mushy. Might be my imagination.

the lower arms remain at an angle that prevents the FEL from seating in the cradle. It feels like the lever doesn’t have enough travel to move the arms back.

I have mounted/unmounted the FEL a few hundred times since I bought it…

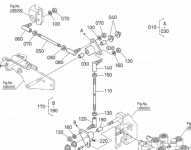

yes, except the rear arms don’t operate properly. I don’t think the lift cylinders are extending all the way.View attachment 763326

if the market wasn’t so wacky, I’d trade the thing in and get the next size up.

I know if I don't have my bucket curled just right I can't get the rear mounts to drop in place. It also hangs up on the brackets sometimes.