rswyan

Super Star Member

- Joined

- May 12, 2004

- Messages

- 13,184

- Location

- Northeast Ohio

- Tractor

- Kubota B2910, Cub Cadet Pro Z 154S, Simplicity 18 CFC, Cub Cadet 782

TLB's (Tractor/Loader/Backhoe)Would be interesting to know if the brackets differ between the ones on our 3240's vs the ones set up as backhoes. I think they are called LTB's?

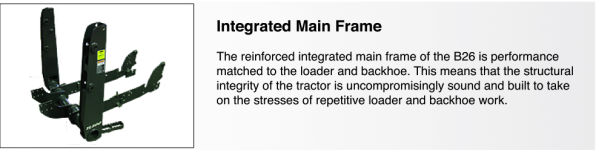

Have a look at the attached picture which I snagged from the "Features" PDF for Kubota's smallest construction/industrial TLB, the B26.

Consider the difference in how it's constructed (loader mount integrated into - and not separate from - the tractor frame) as compared to a normal CUT with an add-on loader: