STx

Veteran Member

- Joined

- Oct 13, 2014

- Messages

- 1,132

- Location

- Bandera, Tx

- Tractor

- New Holland TC40 DA, Deere 17D, Hyster SX50 forklift, Case D450, Kubota ZD1011-54, International Dump Truck, Kubota SVL-952S, Volovo EC250DL

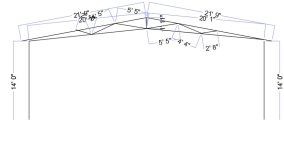

We've finally moved so now I need to build an area to work out of the elements. Budget isn't going to allow doing a fully enclosed building or a concrete slab right now so I'm just building the frame and putting a corrugated tin roof on for now. My plan is to use 2 3/8" drill stem (pipe) for the posts and rafters built sort of like a truss. I'm planning to set the posts on 10' centers (set 4' deep on concrete and with 120# of concrete per post) and the rafters on 4' centers and then bolt 2x4's onto the pipe with brackets on 4' centers to screw my corrugated tin roof onto. Initially, I'll build a 20 x 40 work area so I can cover my container, later expanding that our to 40 x 40 or 60 x 40 as funds allow.

I can get all the material I need for this as I have it designed for about $1,800 but, before I start throwing this up, I thought I'd see what you guys thought of the plan. Attached is a drawing of how I plan to frame it. We have no snow or frost line here but, it does get pretty windy. The soil is mostly sandy loam with some clay for about the first 4' and then caliche below that. If I get down to the caliche in each post hole, I should have a very solid base.

Any feedback, good or bad, is appreciated.

I can get all the material I need for this as I have it designed for about $1,800 but, before I start throwing this up, I thought I'd see what you guys thought of the plan. Attached is a drawing of how I plan to frame it. We have no snow or frost line here but, it does get pretty windy. The soil is mostly sandy loam with some clay for about the first 4' and then caliche below that. If I get down to the caliche in each post hole, I should have a very solid base.

Any feedback, good or bad, is appreciated.