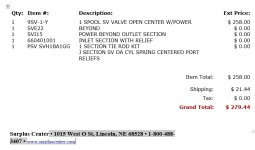

I have a question for you hydraulic masters. When I look at the doc that came with this valve, I see that I'll need to make 5 connections:

1, 2: Work ports to the thumb cylinder - that's easy.

3: In - this is the high pressure line coming from the tractor that formerly went to the backhoe, will now go to this new valve.

4. Power Beyond - this is the high pressure coming out of the new valve. I'll plumb this to feed the backhoe, so connections 3 and 4 are basically inserted into the high pressure line coming from the tractor.

5. Out - The documentation implies that it needs to go to the tank. Do I need this? I'm thinking not, since the backhoe currently runs with only two hoses, so why can't the thumb valve be fed with two hoses? Or is it different if the valve supports power beyond? This may be redundant with questions I asked earlier, so please be patient with me.