CasualObserver

Member

So have a BX2360 here. Broken HST Fan which is not that unusual.

I drilled a 1.5" hole above the fan to easily access the bolt that hold the rear coupling on the tranny side. That allowed me to remove the bolt in under 5 minutes easy as pie. I installed a metal cover which friction fits the hole perfectly.

Going to slide the engine forward with a hoist I borrowed from a friend. Would prefer not to buy yet another 150+ pound chunk of metal for a one or two time time use if this happens again.

I saw in another thread here or on orangetractor that someone suggested possibly cutting the shaft when it was off and fitting it with a rigid two piece coupling. Idea is that in the future if the fan should be hit again the coupling can be removed and the rear portion of the shaft easily removed without messing with the engine side at all.

Looking at the specifications for the coupling at Mcmaster for the following part:

McMaster-Carr

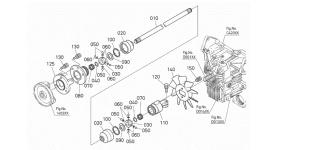

Image of the coupling:

I measured the shaft as 20mm.

Specifications from the site:

Material: Steel

For Shaft Diameter: 20mm ï¾— 20mm

Overall Length: 65mm

OD: 42mm

Maximum Speed: 4,000 rpm

Maximum Torque: 3,095 in.-lbs.

For Shaft Type: Round ï¾— Round

For Shaft Misalignment Type: None

For Motion Type: Forward/Reverse, Start/Stop, Continuous

When I looked into the details of the engine torque for the BX2360 I found max torque of 44 foot-pounds which converts to 528 inch-pounds. Since the part is rated at 3095 inch-pounds it should be able to handle the torque fine.

Link to Torque chart for the Kubota D902 engine:

DieselEngineMotor.Com - Kubota Diesel Engine D92

Part is available for $56 plus tax delivered.

So what are your thoughts on this? Are my torque figures wrong? Am I crazy to even think about doing this? Please give me your feedback negative or positive.

Thanks!

I drilled a 1.5" hole above the fan to easily access the bolt that hold the rear coupling on the tranny side. That allowed me to remove the bolt in under 5 minutes easy as pie. I installed a metal cover which friction fits the hole perfectly.

Going to slide the engine forward with a hoist I borrowed from a friend. Would prefer not to buy yet another 150+ pound chunk of metal for a one or two time time use if this happens again.

I saw in another thread here or on orangetractor that someone suggested possibly cutting the shaft when it was off and fitting it with a rigid two piece coupling. Idea is that in the future if the fan should be hit again the coupling can be removed and the rear portion of the shaft easily removed without messing with the engine side at all.

Looking at the specifications for the coupling at Mcmaster for the following part:

McMaster-Carr

Image of the coupling:

I measured the shaft as 20mm.

Specifications from the site:

Material: Steel

For Shaft Diameter: 20mm ï¾— 20mm

Overall Length: 65mm

OD: 42mm

Maximum Speed: 4,000 rpm

Maximum Torque: 3,095 in.-lbs.

For Shaft Type: Round ï¾— Round

For Shaft Misalignment Type: None

For Motion Type: Forward/Reverse, Start/Stop, Continuous

When I looked into the details of the engine torque for the BX2360 I found max torque of 44 foot-pounds which converts to 528 inch-pounds. Since the part is rated at 3095 inch-pounds it should be able to handle the torque fine.

Link to Torque chart for the Kubota D902 engine:

DieselEngineMotor.Com - Kubota Diesel Engine D92

Part is available for $56 plus tax delivered.

So what are your thoughts on this? Are my torque figures wrong? Am I crazy to even think about doing this? Please give me your feedback negative or positive.

Thanks!

Last edited: