I have this aerial lift.

I'm trying to figure out how the hydraulics that control the operator cage leveling work. As the cage is raised or lowered by the boom, there is a small hydraulic cylinder directly under the cage that extends or retracts to keep the cage level. The operation is hydraulic, there's no electronics or wires involved. The service manual gives vague instructions how to rebuild the cylinder but no explanation how it works. I'm assuming it must be sensing the relative pressure between the two cylinders that control the position of the lift arms because that gives you an indirect indication of the relative angle of the two lift arms.

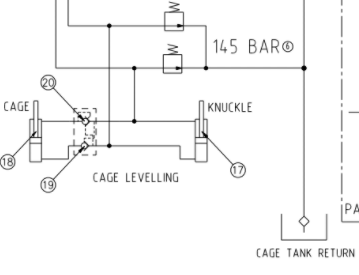

Here's the part of the hydrauilc diagram that shows the leveling cylinder that lives under the cage:

Parts 19 and 20 are listed as check valve and overcenter valve respectively. Can anybody get me pointed in the right direction on how this thing works. It's not functioning quite properly but I don't want to get into that until I have some idea how it works.

I'm trying to figure out how the hydraulics that control the operator cage leveling work. As the cage is raised or lowered by the boom, there is a small hydraulic cylinder directly under the cage that extends or retracts to keep the cage level. The operation is hydraulic, there's no electronics or wires involved. The service manual gives vague instructions how to rebuild the cylinder but no explanation how it works. I'm assuming it must be sensing the relative pressure between the two cylinders that control the position of the lift arms because that gives you an indirect indication of the relative angle of the two lift arms.

Here's the part of the hydrauilc diagram that shows the leveling cylinder that lives under the cage:

Parts 19 and 20 are listed as check valve and overcenter valve respectively. Can anybody get me pointed in the right direction on how this thing works. It's not functioning quite properly but I don't want to get into that until I have some idea how it works.