Just thinking today, yea i know, it bad for ones health......

I could get many running 3.5HP briggs freeish. 3.5's in themselves aint too good for much. can i weld engines together output shaft to flywheel, thus making the overall output more?

/forums/images/graemlins/grin.gif /forums/images/graemlins/grin.gif /forums/images/graemlins/grin.gif /forums/images/graemlins/confused.gif

might work?

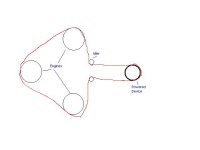

the pic demonstates the idea

I could get many running 3.5HP briggs freeish. 3.5's in themselves aint too good for much. can i weld engines together output shaft to flywheel, thus making the overall output more?

/forums/images/graemlins/grin.gif /forums/images/graemlins/grin.gif /forums/images/graemlins/grin.gif /forums/images/graemlins/confused.gif

might work?

the pic demonstates the idea

Last edited: