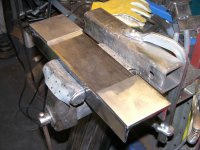

Sort of a "sneak preview", I got just enough done to see where the previous parts will go;

Left and right ends, from below -

Top view, from above the I beam -

One of the post-mounted spreaders drilled -

One of the diagonal tube gussets ALMOST in place -

the post mounted spreader (channel) will get notched out so the 45 deg. angle end can sit flat inside the channel, then everything will get fiddled with til the gaps go away

- then I'll tack everything (with all the spreader bolts tight), then take both braces down and weld 'em out using the "hopscotch" method

combined with "kopius kwantitys of Klamps"...

But probably NOT today; still have the other post-mounted spreader to drill and chamfer, get all the spreaders square to their mounting locations (and aligned so everything fits), run a 240 extension cord out there, move the MM211 out there using "hand truck mode", wait for the dang wind to pause for a breath

Still, it was nice being able to get an idea of how it'll go - those gusset tubes will be 10" apart inside, and the biggest hoist I'll be using on this crane is 8" wide - this design lets me get a long enough gusset to really solidify the post mounts WITHOUT having to give up a couple feet of travel on each end of the beam... Steve