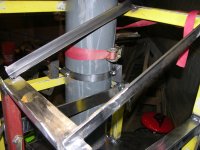

Went looking and found a "slightly used" barn door hinge that'll do for the one end of the tank strap - it'll get "MMM'd" (Mashed, Maimed, Mutilated) and "SS'd" (ShinySteve'd) and painted with the "NQMB" (NotQuiteMillerBlue) paint, so it's all good - grabbed a 3/8 bolt/nut/washer for the tightener;

After lunch I'll cut a piece of 1/8x2 strap, drill a hole in one end, bend a 90* there, weld a nut over the hole, clamp a couple long 5/8 bolts in the vise and "incrementally" bend the strap into a precise

7.5" diameter half-circle, weld the NON-bent end of that to the barn hinge, chop off all but an inch of the OTHER leaf of the hinge, weld the hinge to the corner upright (maybe), then cut a short piece of angle for the OTHER anchor point - if I kin keep it to less than 3 or 4 "do-overs" I might have it done by supper (it's good to have dreams

)

Sorry Terry, I REALLY like your bottle clamps; just not enough to spend THAT much time fabbing one from SCRATCH when my feet get numb quicker than the job gets done

Story time - I'd use my slip roll to bend that strap, but it's not back together totally yet - it was a CL find, guy selling it was the

SON of the guy that built it for the company I worked for my last 25 years; he built it about

20 years before I worked there.

They used it to

roll rings out of 1" thick steel, 14" wide and 48" diameter.

When I worked there they had farmed out THAT part of the job - but I ended up making a Safety Video of the CORRECT process after one of our "dumb and proud of it" weldors screwed that job up and

lost his leg from the knee down...

The son of the guy that

BUILT the slip roll ran a 3 foot wide piece of 1/4 plate thru it when I wuz looking at it, came out about the same curve as those hose hangers in one of my pics, and the roll

didn't even slow down or groan. Probably 'cause that gearbox below the drive roll is 171:1 IIRC - and the motor and gearbox pulleys gear THAT down ANOTHER 3:1...

I didn't like the strange base he had on it so changed it to be compatible with either forks or a pallet jack- but the electrical was kinda funky, so before it goes back together completely I'll need to get a new reversing lathe-type switch - also need to change the top roll for easy on/off.

Still,

18 gauge powered ones that width (50") go for about $6 grand new, so $400 didn't make me cry much :thumbsup: ... Steve

Oh, the driven roll ALSO drives a ring roller that mounts on the far end - has 5-6 dies for that too -